Downstream - precision and safety in processing

Process pumps for refinery applications and petrochemical stations

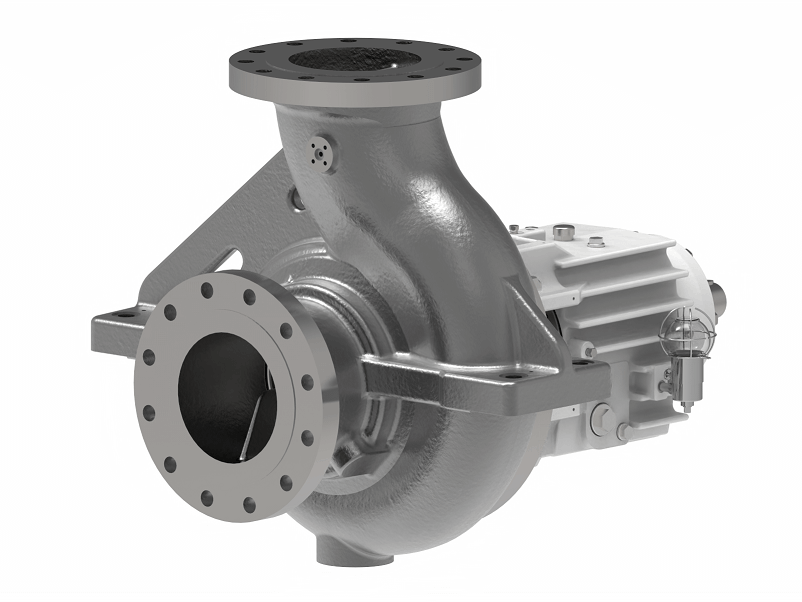

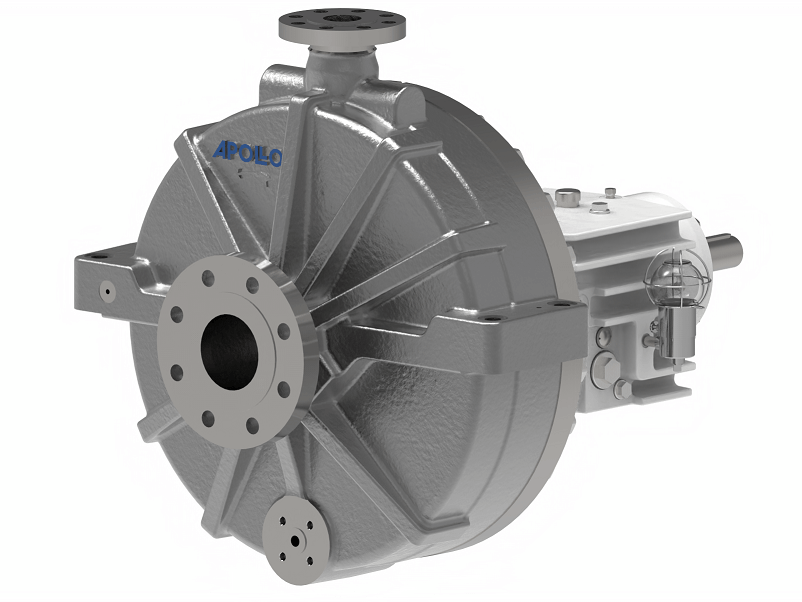

In the downstream market, Apollo supports the conversion of raw materials into finished products through the use of high-performing pumps in accordance with API 610. As an experienced partner to the oil and gas industry, we offer a comprehensive range of products that are individually customised to meet specific process requirements. We meet all requirements for the transfer of corrosive media and ensure safe and efficient operation.

For applications in the downstream field, we offer refinery pumps, high-pressure pumps for petrochemical plants, pumps for transporting distillation bypass streams, pumps for secondary process systems and for transporting end products and secondary products.

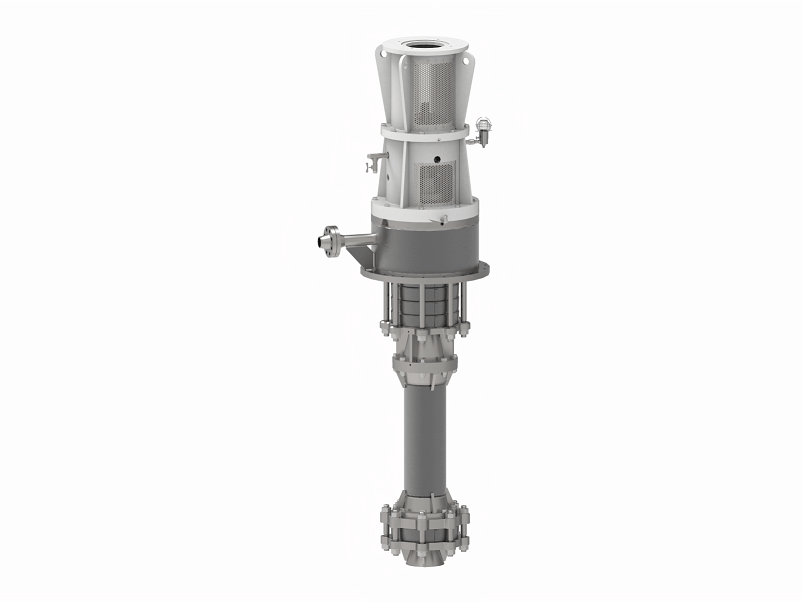

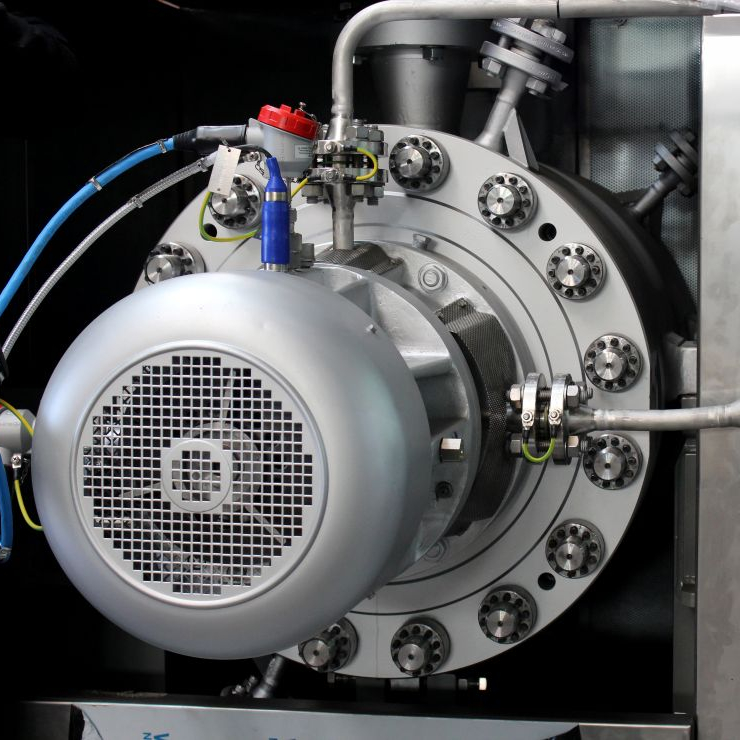

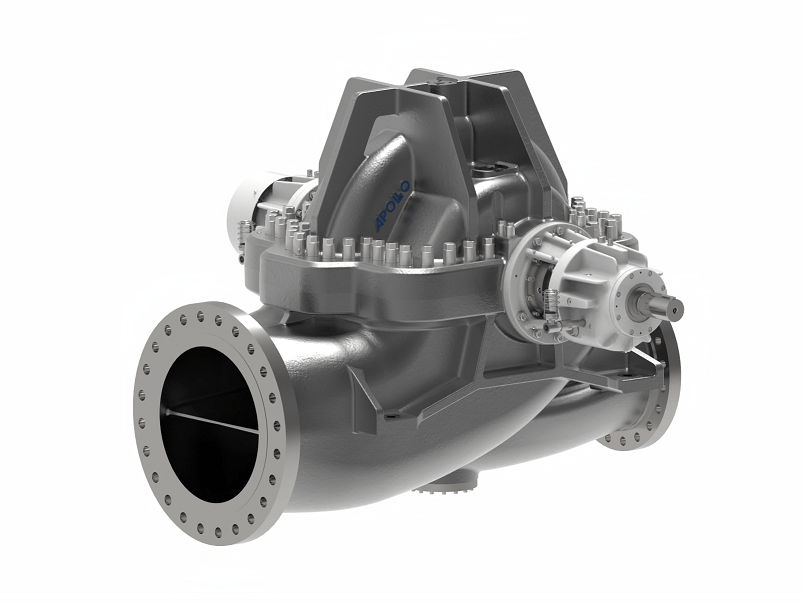

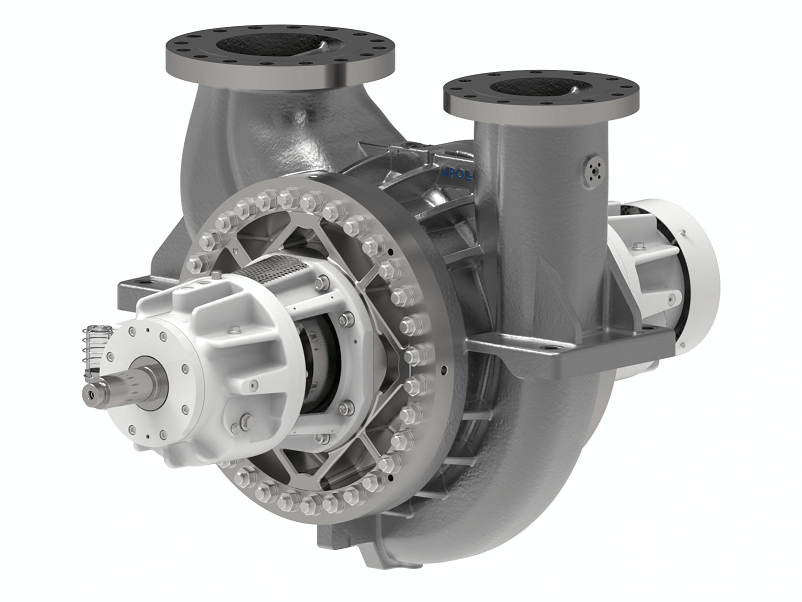

Apollo supplied 150 pump units as a complete solution for an international oil refinery. The project included API 610-compliant process pumps of the following types: BB1, BB2, BB3, BB5, OH2, OH3, VS1, and VS4. These pumps are designed to handle demanding liquids, such as naphtha, feed water, sour water, diesel, hydrocarbons, propane, and liquid gases. These pumps can operate in temperatures ranging from -46°C to 350°C and meet the strictest standards for material resistance and safety.

All materials comply with international standards, including API, ASME, ASTM, EN, ISO, NACE, and NORSOK. In addition to ferritic and austenitic cast steel, duplex, super duplex, and titanium are also used. Apollo is one of a select few manufacturers that supply titanium pumps, which are characterized by their high corrosion resistance, even in aggressive liquids.

Particular challenges of this project included pumping media containing hydrogen sulfide and amines and designing a VS4 vertical pump with OH2 hydraulics for corrosive caustic soda (NaOH) solutions. Special design measures were implemented for applications with extreme temperature fluctuations to absorb temperature shocks and ensure maximum operational safety.

Thanks to our many years of engineering expertise, flexible material selection, and comprehensive experience, we were able to precisely and reliably implement all customer-specific requirements. The wide range of products enables solutions for all refinery sectors — from standard applications to highly specialized processes.

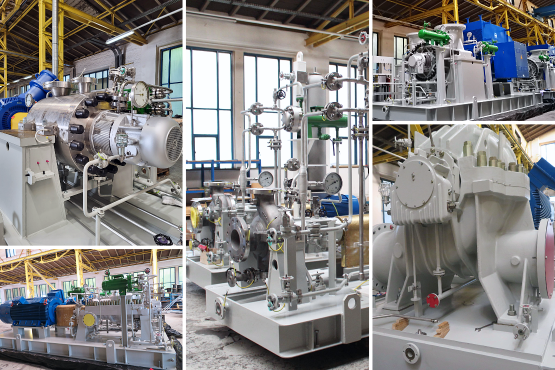

Major order for delivery of process pumps to petrochemical complex

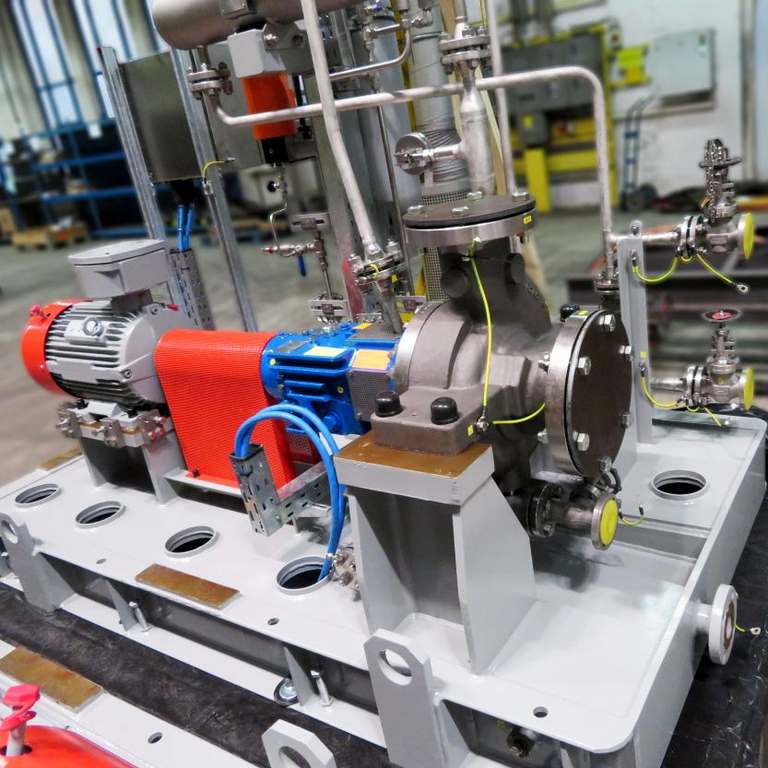

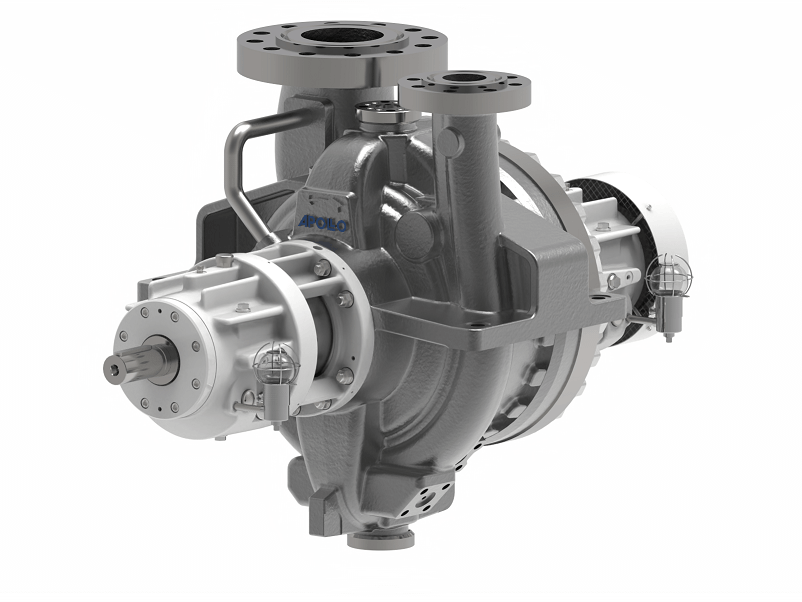

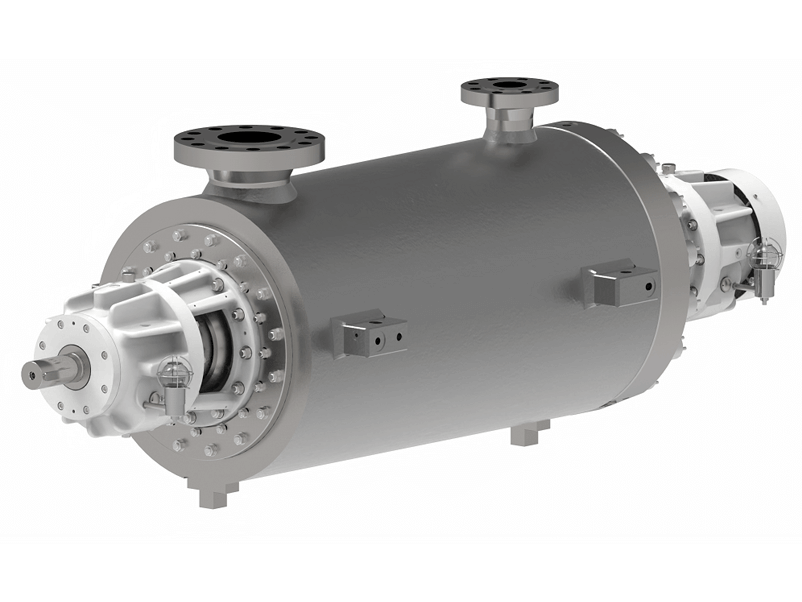

Apollo supplied various centrifugal pumps in accordance with API 610 for a production plant manufacturing phenol and acetone. These pumps are specially designed to meet the high requirements of the petrochemical industry. These pumps can reliably fulfil demanding operating conditions and specific customer requirements relating to flow rate, design pressure and material resistance.

The delivery included AMG boiler feed pumps (API 610, BB3), numerous single-stage process pumps (API 610, OH2), multi-stage reactor pumps (API 610, BB5) and BB2 process pumps. The use of materials such as duplex and super duplex steels ensures high resistance to pumped media such as condensates, carbonates and ethylene glycol mixtures.

Want to know more?

For over 160 years, Apollo Goessnitz GmbH has been a leading German manufacturer of industrial pumps and pump systems. As a European specialist in customized pump technology, we serve customers in the energy, chemical, and oil and gas industries around the globe. Our focus is on reliability, efficiency, and sustainable solutions.

Download Brochures

*The above product overview is for reference purposes only and provides an overview of the basic range of products manufactured by Apollo. Additional pump types and systems, as well as detailed technical information and product/industry-specific classifications, are available from Apollo upon request.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/a/csm_BB3-AMG_95c3692be4.jpg)

![[Translate to English:]](/fileadmin/_processed_/0/9/csm_BB5-TG-80M-15.20_a60e91da74.png)