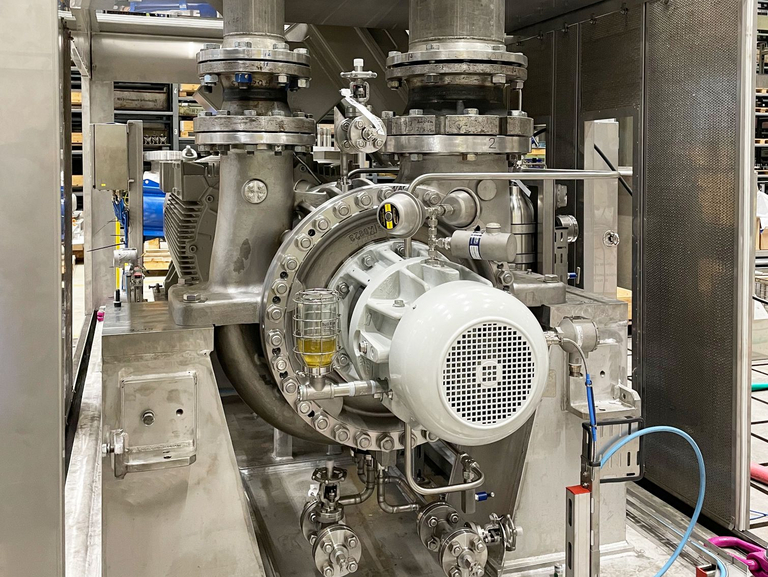

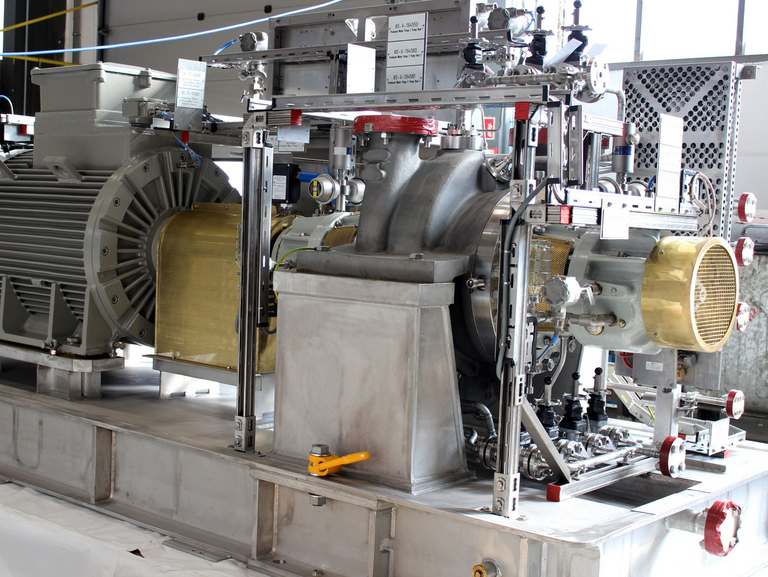

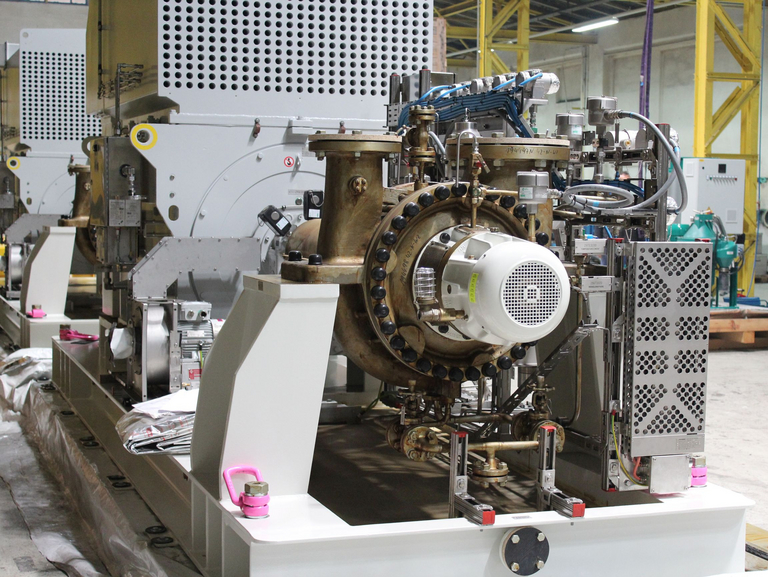

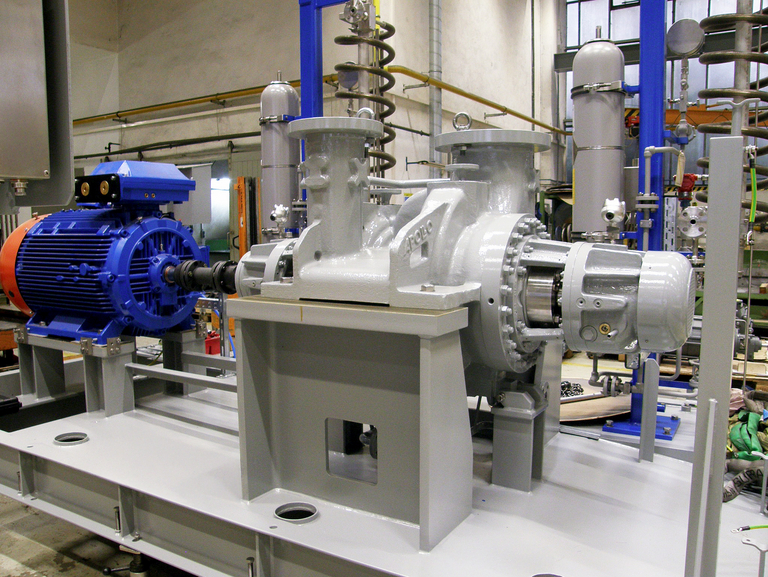

Radially split, single- and two-stage, double-suction process pumps for high-pressure and high-temperature applications

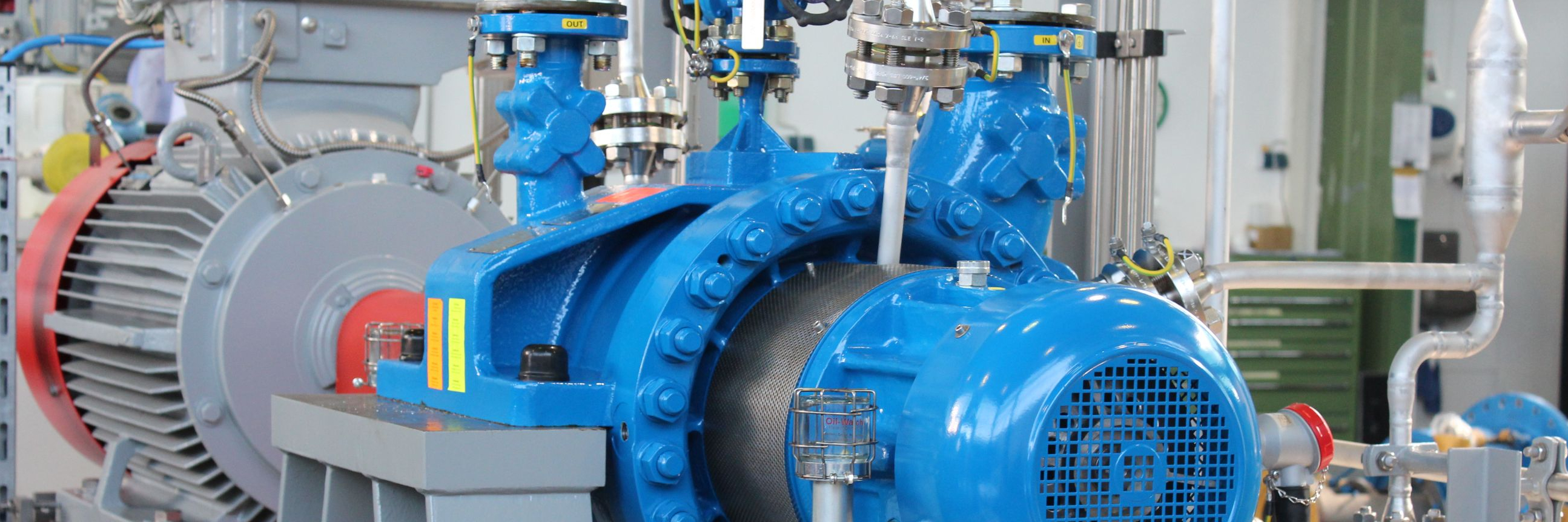

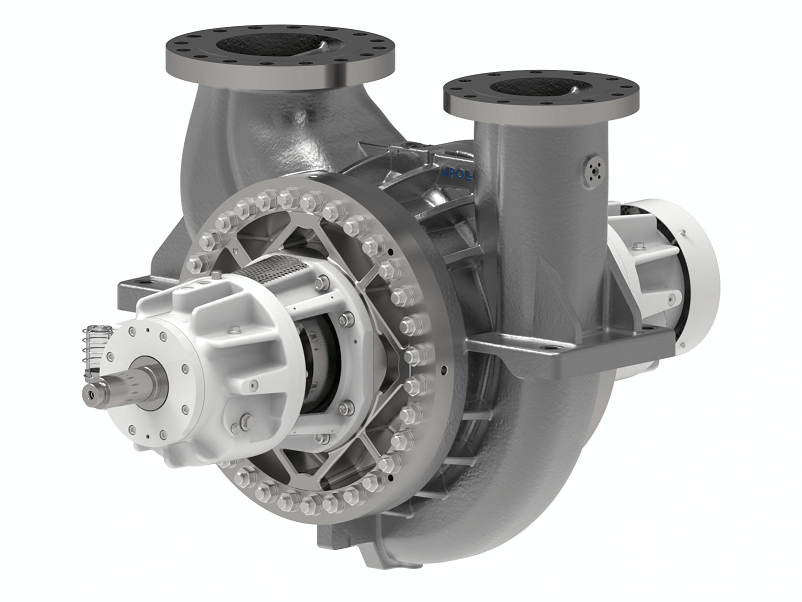

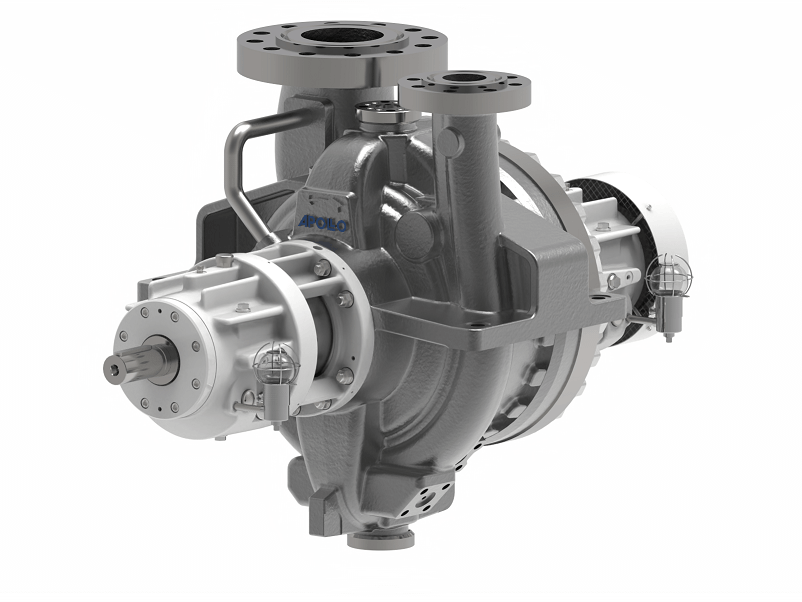

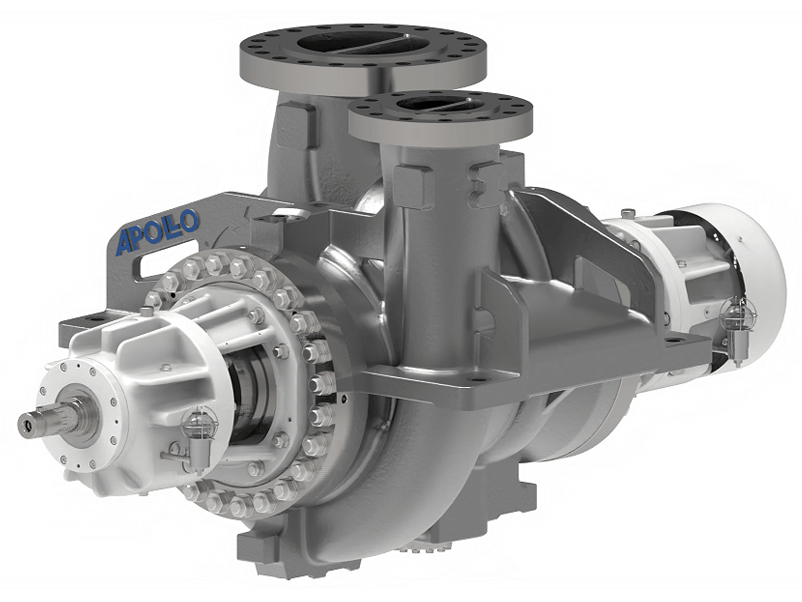

Horizontal, single- and two-stage, radially split, double-suction BB2 pumps according to API 610 are designed for the most demanding operating conditions in the oil, gas, energy and process industries. They feature a radially split casing (i.e. transverse to the shaft axis) and a rotor mounted between the bearings. This configuration provides maximum stability at high pressures, temperatures and long running times.

The centreline-mounted casing design safely absorbs thermal expansion and maintains system alignment even under high-temperature conditions. The pumps are available in single- or two-stage versions with single or double suction impellers. BB2 pumps cover a wide range of delivery heads and are suitable for a variety of critical process tasks.

Apollo Gößnitz offers BB2 pumps in various configurations, including single-stage, radially split spiral casing pumps with double volutes and double suction impellers, and specialised high-performance variants with an axial inlet and semi-open impellers in a two-stage back-to-back design in accordance with API 610. Vertical versions with bearings on both sides are also available.

Thanks to their robust construction, API compliance and high mechanical stability, BB2 pumps are ideal for demanding processes such as oil and product pipelines, refinery and petrochemical applications, water injection, boiler feed water and other high-pressure, high-temperature services.

Advantages of API 610 BB2 pumps:

- Radially split casing for safe operation at high pressures and temperatures

- Double-flow impellers for optimum NPSH values

- Available as single-stage or two-stage pumps with single or double suction impellers

- Individually configurable casing design to meet customer requirements

- High operational reliability even with demanding process media

Typical applications:

- Oil and product pipelines

- Oil transfer and tank farm processes

- Water injection in the oil and gas industry

- Refinery and petrochemical processes

- Boiler feed water, condensate, and booster pumps in power plants

- High-pressure process and auxiliary services in chemical applications and the energy industry

Want to know more?

Apollo Goessnitz GmbH - European pump manufacturer from Germany. We stand for quality and innovative solutions in customised pump technology.