HYDRAULIC POWER RECOVERY TURBINE

Maximum energy efficiency with HPRT in industrial processes

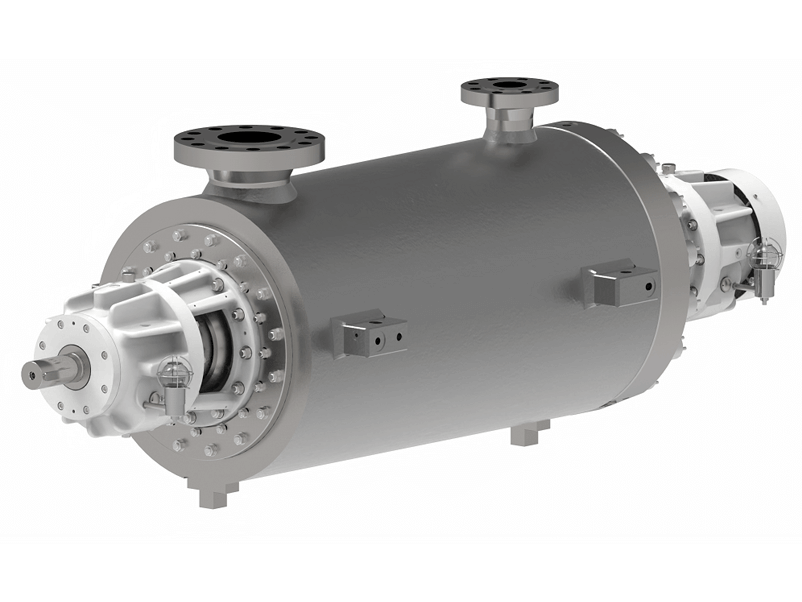

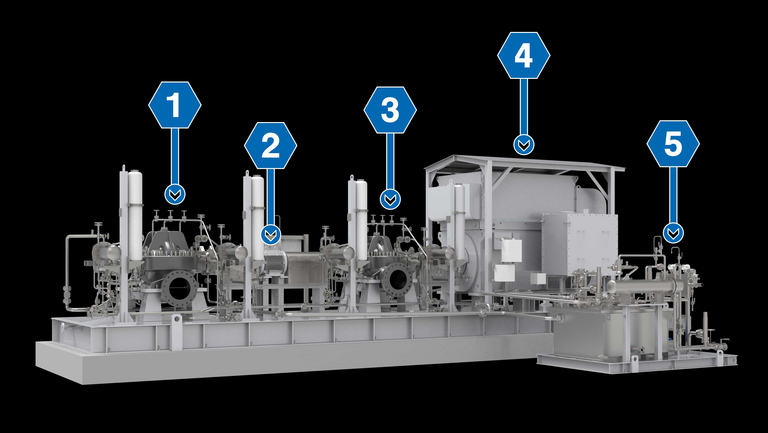

Apollo Gößnitz GmbH offers the Hydraulic Power Recovery Turbine (HPRT), an efficient solution for recovering hydraulic energy in industrial processes. The HPRT utilises the pressure potential within a process to convert potential energy into mechanical energy. This technology can significantly reduce energy consumption and optimise pump systems.

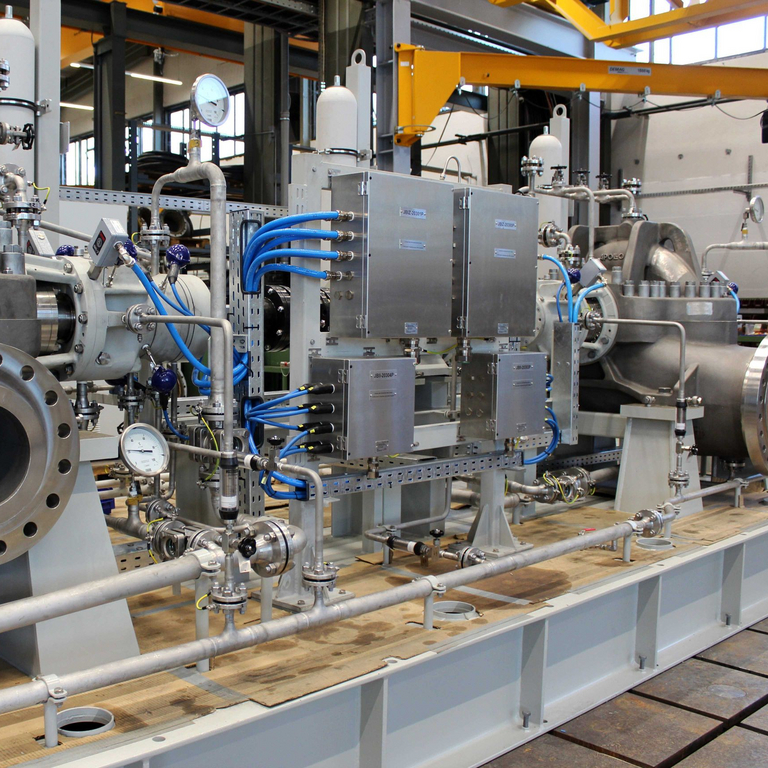

The automatic over running clutch is used to achieve precise speed control. It automatically disconnects as soon as the HPRT starts to rotate more slowly than the pump. This ensures that torque is only transmitted once the two components are moving at the same speed. This guarantees efficient and smooth operation.

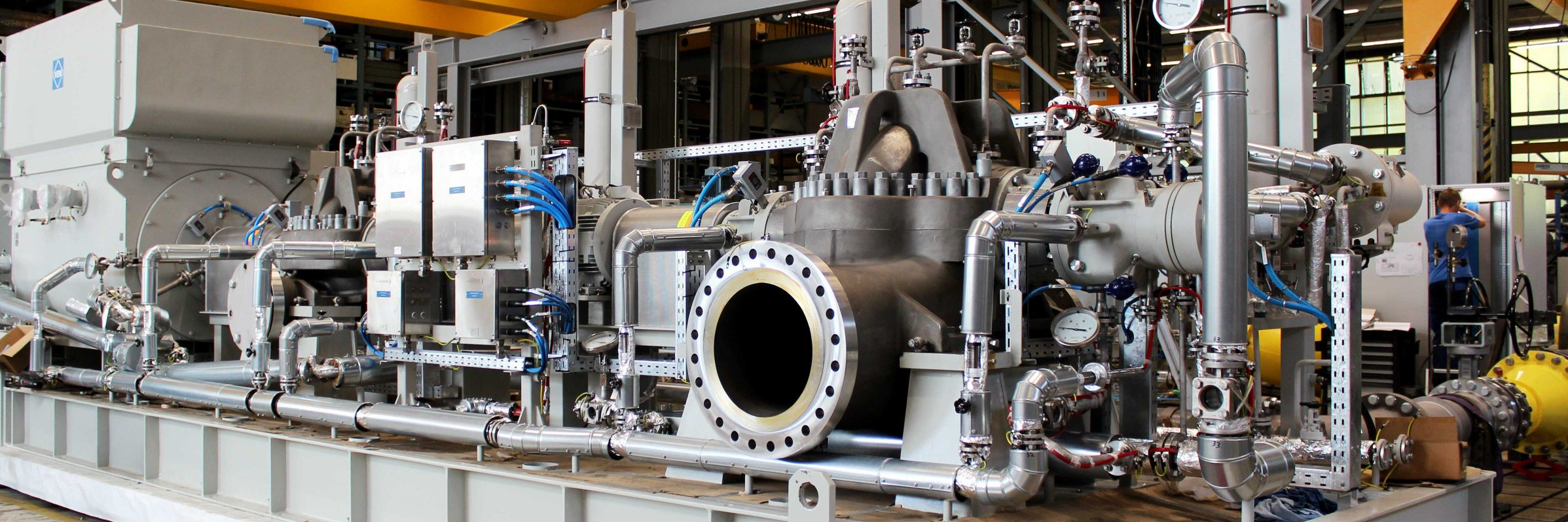

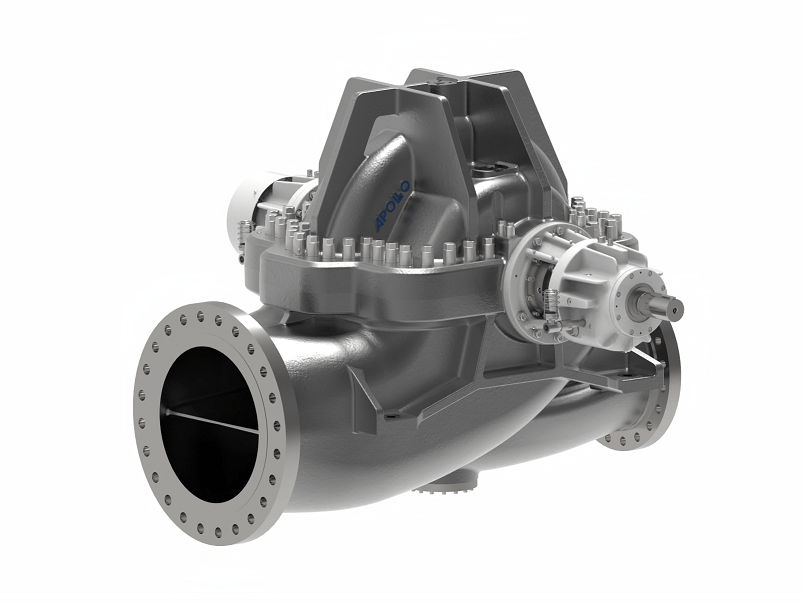

The Apollo ZMK is an axially split, single-stage BB1 process pump that complies with the API 610 standard. In this application, the pump delivers 1,500 m³/h of semi-lean Amdea solution, with a delivery head of 350 metres and power consumption of approximately 1.8 MW. The material complies with API Class A-8, ensuring a robust and corrosion-resistant design.

Designed in accordance with API 614, the Apollo lubricating oil system ensures a reliable and continuous oil supply for the bearings of centrifugal pumps, HPRTs and electric motors, as well as the antifriction bearings of the clutch. Thanks to its precise design, the system minimises wear and significantly increases operational reliability. Its modular design allows it to be adapted flexibly to individual plant situations, ensuring optimal integration into the application.

Typical applications for HPRT

Apollo's Hydraulic Power Recovery Turbine (HPRT) is used in a variety of demanding industrial applications. An HPRT can be used wherever the system pressure needs to be reduced to meet the requirements of subsequent processes or to relieve excess pressure. Unlike a conventional throttling device, an HPRT recovers energy rather than dissipating it as heat. Typical areas of application for HPRTs include:

- refineries and petrochemical plants

- natural gas processing

- fertilizer factories

- power plant technology

- pump systems with high pressure loss

Centrifugal pumps compatible with HPRT

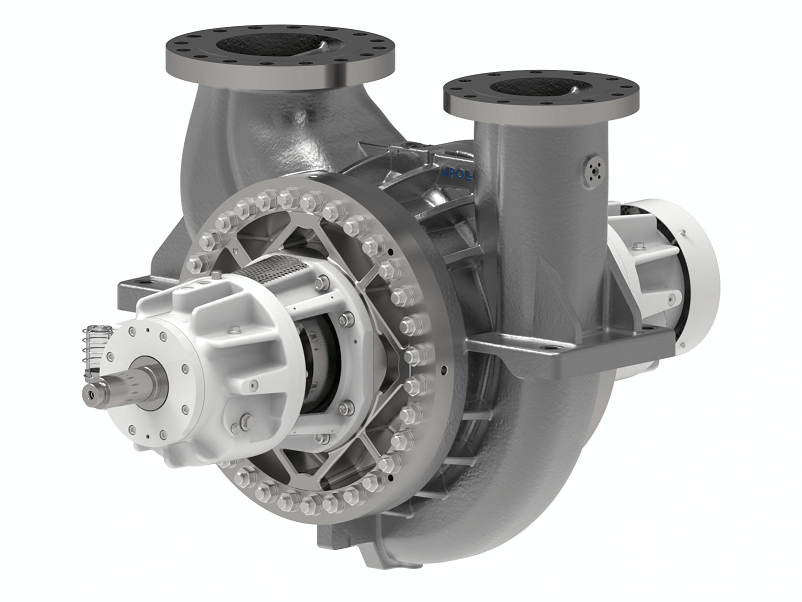

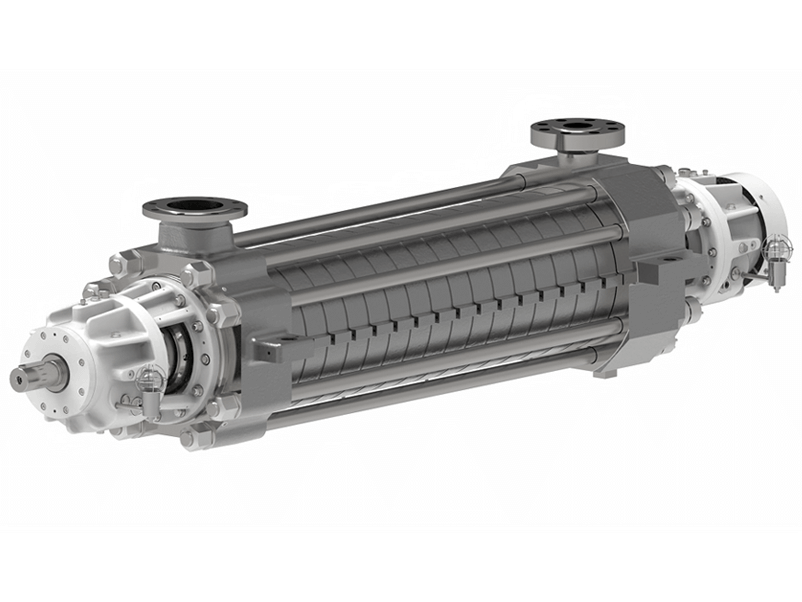

The selection and design of an HPRT essentially follows the same principles as the dimensioning of pumps. Although they are referred to as turbines, HPRTs are based on the design of centrifugal pumps, with the flow of the medium reversed. Regardless of their specific speed, design (horizontal or vertical) or whether they are single-stage or multi-stage, numerous centrifugal pumps can be operated in reverse. Therefore, they can be used as HPRTs.

The common types of pumps that are often used in combination with HPRT require special design modifications to their construction and hydraulic components. These pumps include:

Want to know more?

Apollo Goessnitz GmbH - European pump manufacturer from Germany. We stand for quality and innovative solutions in customised pump technology.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/a/csm_BB3-AMG_95c3692be4.jpg)

![[Translate to English:]](/fileadmin/_processed_/0/9/csm_BB5-TG-80M-15.20_a60e91da74.png)