LUBE OIL SYSTEMS

FOR PROCESS PUMPS AND INDUSTRIAL UNITS

Apollo Gößnitz's lubrication systems are designed and manufactured according to current standards and norms, including API 614, as well as the manufacturer's own specifications. These systems ensure a reliable oil supply for pumps, gearboxes, turbines, motors, bearings, and other machine components. The systems' primary function is to minimize friction and wear, thereby extending the service life of the equipment and significantly reducing maintenance and operating costs.

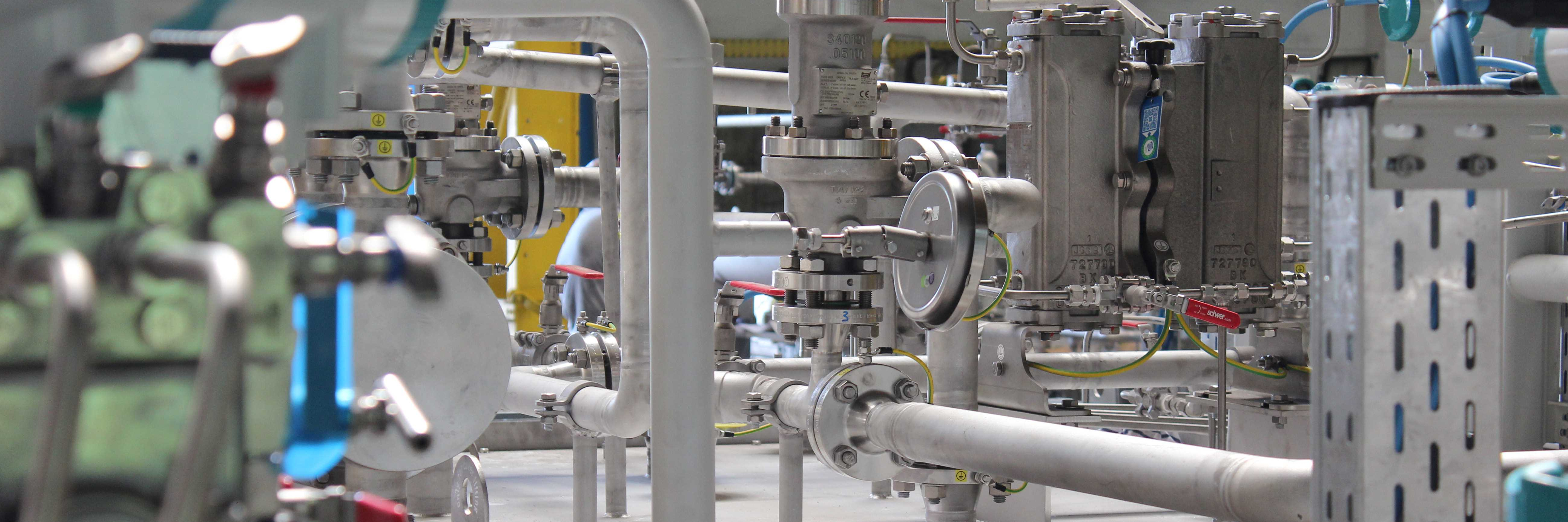

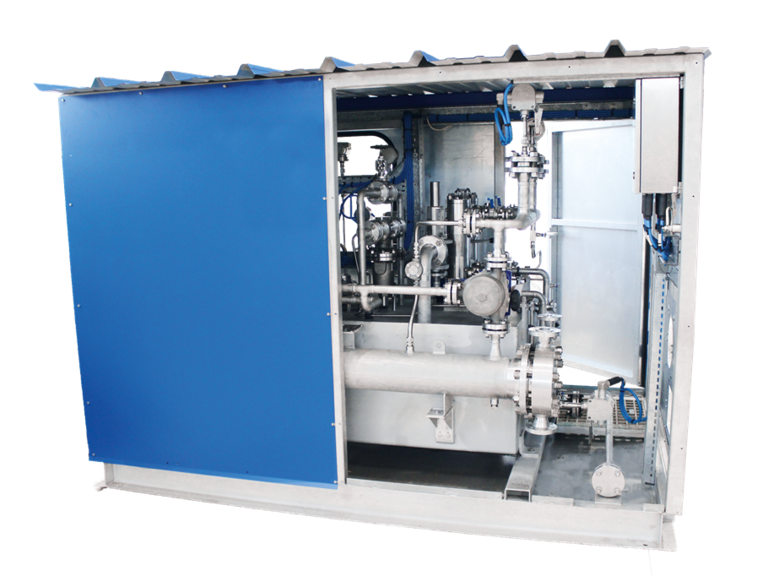

Different designs are used depending on the application and size. Process pumps that comply with API 610 utilize either integrated bearing housings with a local oil sump, oil bath, ring, or oil mist lubrication or are connected to centralized circulating lubrication systems for large and critical machines. These external systems consist of a tank, pumps, filters, and coolers. They provide defined pressures, flow rates, and oil grades in accordance with API 614.

Integration is achieved via clearly defined interfaces between the lube-oil skid, piping, and bearing housings. Monitoring technology, such as oil level indicators, temperature and pressure sensors, differential pressure monitoring, and bearing temperature sensors, ensures compliance with operating limits. These signals are integrated into the pumps to enable automatic protection functions, shutdowns, or switching to backup pumps in the event of malfunctions.

Apollo's lubrication systems are used in demanding industrial processes in refineries, petrochemical plants, power plants, and the oil and gas industry, for example. They offer maximum operational reliability and efficiency wherever high availability, defined safety requirements, and reliable lubrication design are crucial.

Want to know more?

Apollo Goessnitz GmbH - European pump manufacturer from Germany. We stand for quality and innovative solutions in customised pump technology.