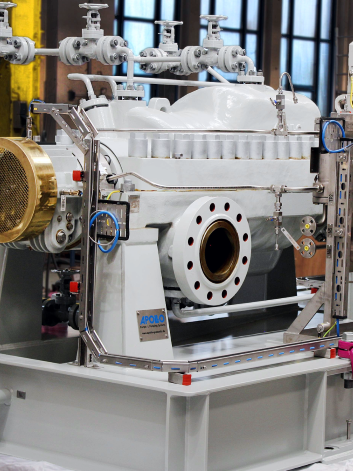

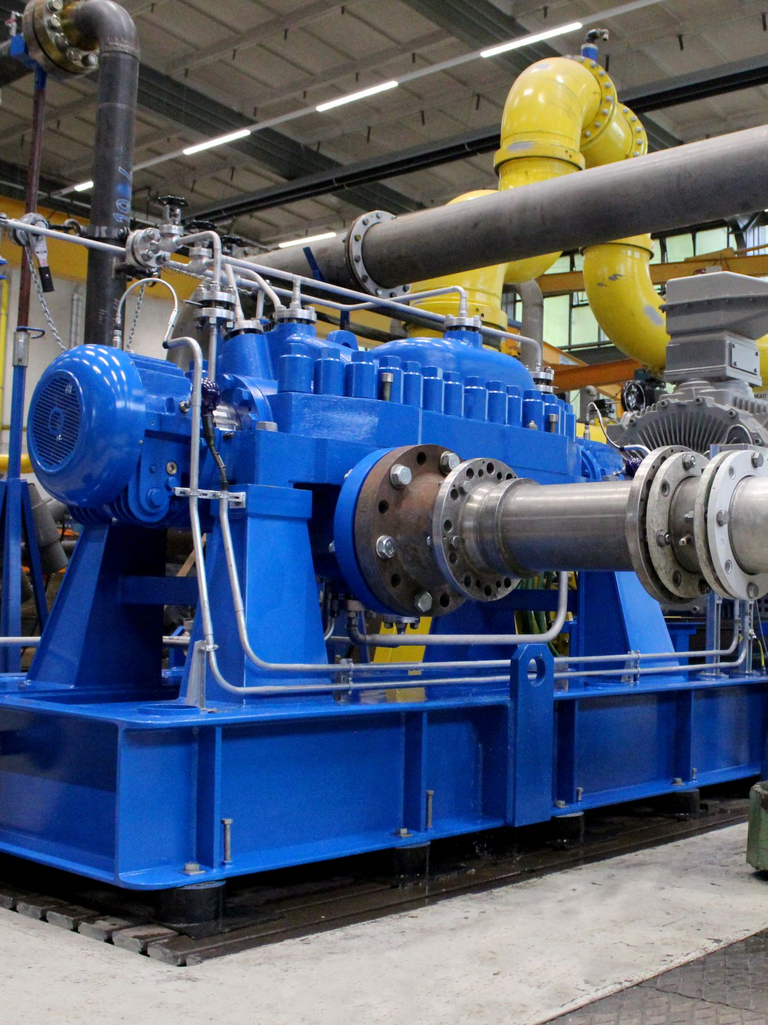

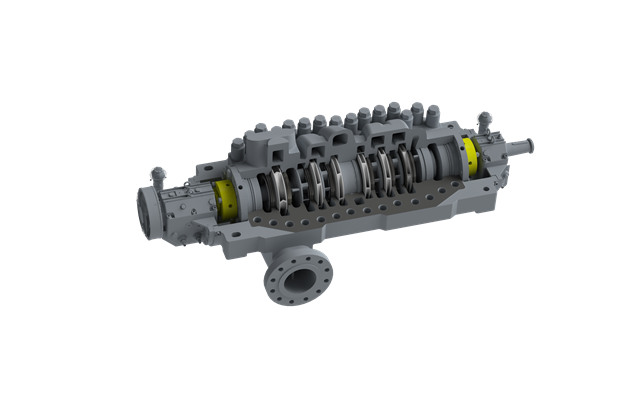

The Apollo-AMG process pump, which complies with API 610 Type BB3, is a horizontal, multistage, axially split, high-pressure pump. It is characterised by its robust housing design and construction, and its long service life. The back-to-back rotor minimises axial thrust, and the optimised rotor dynamics ensure safe operation at high speeds. This guarantees efficiency and performance in critical operating environments.

It is designed for demanding applications in the energy, oil and gas industries, as well as in chemical process engineering, power and water treatment plants, and petrochemical plants.

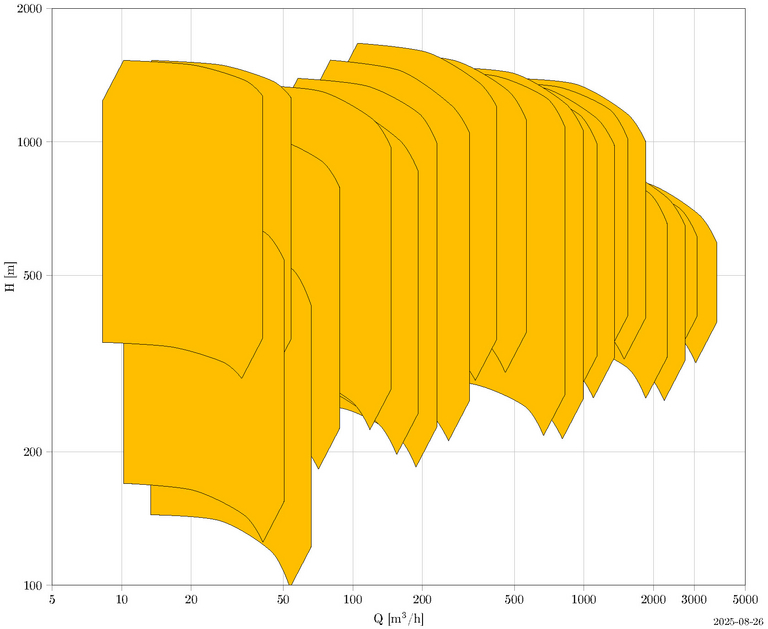

Thanks to their excellent hydraulic characteristics, perfectly optimised performance range and modern structural design, these pumps are suitable for a variety of applications, including:

- applications in energy generation (renewable and conventional)

- refinery applications

- offshore applications

- booster applications in all industrial sectors

- pipelines for water or refined products

- water injection onshore and offshore

- boiler feed water applications

Axially split high-pressure pump with centre support on both sides: Offers increased stability and service life.

Counter-rotating impellers: Ensure optimum axial thrust compensation and reduce mechanical stress.

Specialised NPSH impeller in the first stage: Optimises cavitation characteristics and improves pump performance.

Bearing design: Available with roller or plain bearings for flexible use and increased operating comfort.

Reduced downtime: The axially split housing allows maintenance and inspection work to be carried out while the lower part remains on the pipeline; dismantling of the coupling is not necessary.

We offer materials such as cast steel, chrome steels, austenitic steels, duplex, super duplex, titanium and special alloys in accordance with NORSOK and NACE standards, which provide maximum corrosion and wear resistance.

Selection is made on a customer-specific basis to ensure optimum adaptation to respective process conditions.

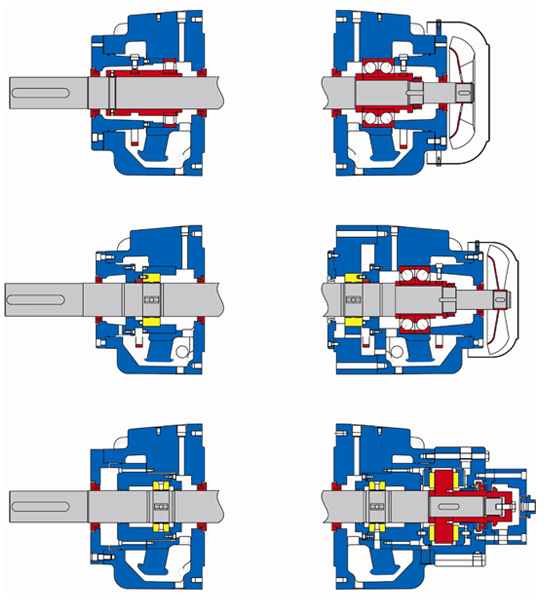

- Standard Version

Radial bearings: antifriction bearings

Axial bearings: antifriction bearings

Ring oil lubrication

- Variant

Radial bearings: slide bearings

Axial bearings: antifriction bearings

Ring oil lubrication

- Variant

Radial bearings: slide bearings

Axial bearings: slide bearings

Pressure oil lubrication

Type series: AMG

Want to know more?

Apollo Goessnitz GmbH - European pump manufacturer from Germany. We stand for quality and innovative solutions in customised pump technology.

![[Translate to English:]](/fileadmin/_processed_/a/0/csm_Booster_Pump_Apollo_BB3_0681ced43a.jpg)