Process pumps and system technology for the fertiliser industry

Apollo Gößnitz GmbH offers specialized pump solutions and system technology for the demanding needs of the fertilizer industry. With many years of industry experience, Apollo guarantees maximum operational reliability, durability, and corrosion resistance — even with aggressive materials such as ammonia, urea, and methyldiethanolamine (MDEA). Robust design and the selection of high-quality materials ensure reliable performance during continuous operation. In addition to manufacturing customized pump types, Apollo offers comprehensive services and technical advice for integrating and maintaining pump systems in fertilizer production.

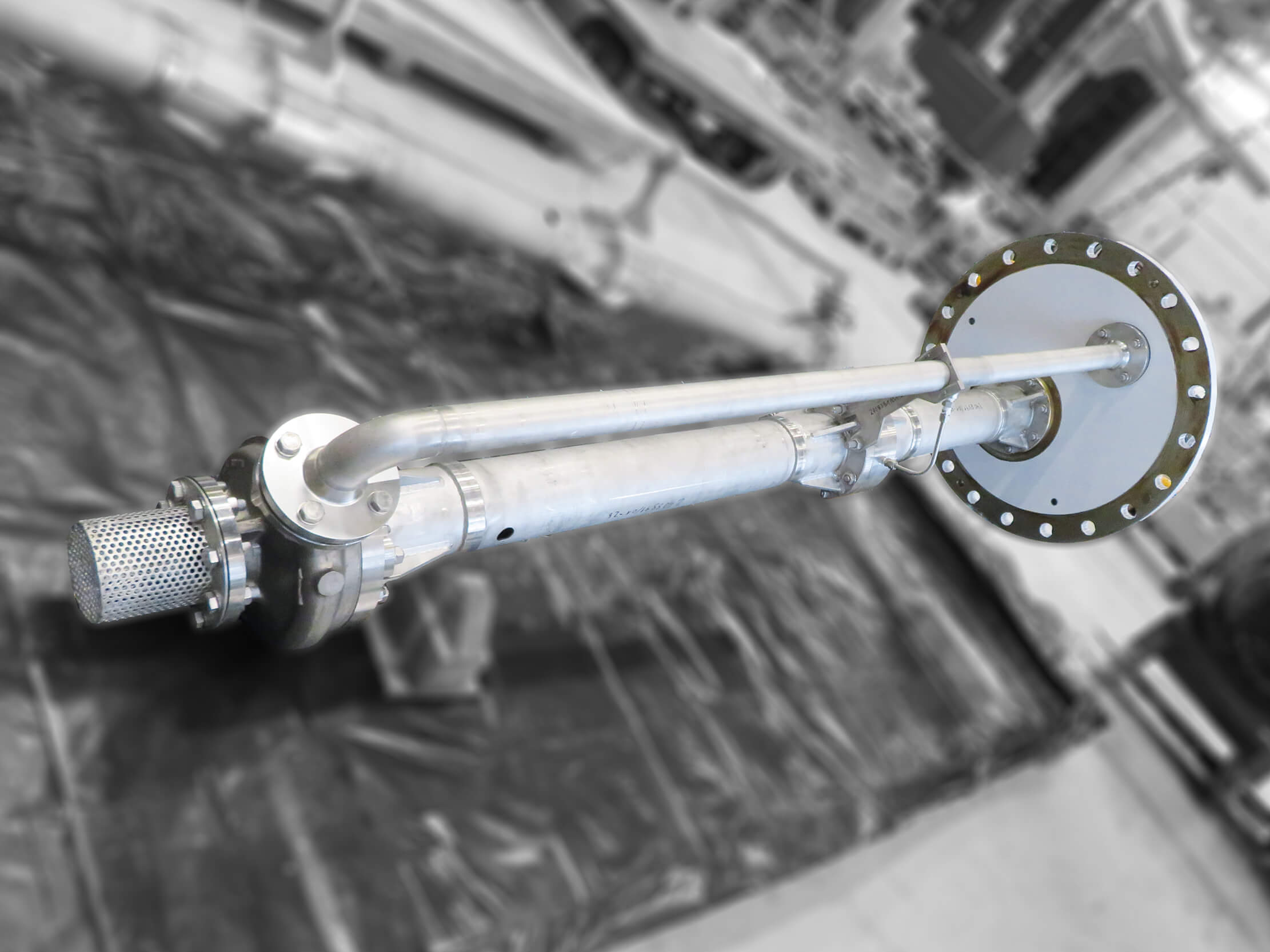

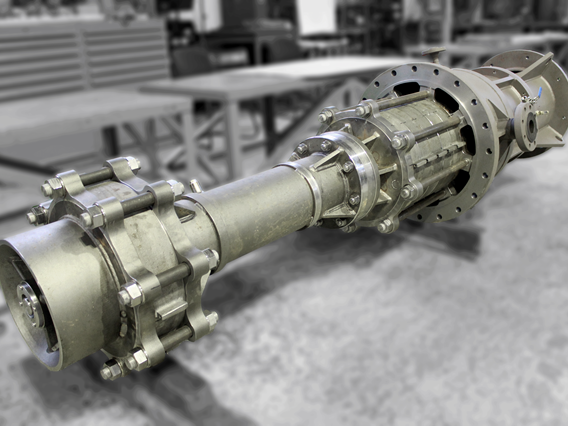

Can-type pumps for demanding ammonia applications in fertilizer production

Apollo Gößnitz GmbH supplied GLKV and HPTV vertical multistage pot pumps for a fertilizer production plant.

The GLKV pump is designed specifically for loading liquid ammonia wagons and can deliver up to 200 m³/h of liquid ammonia at a delivery head of 190 m.

The HPTV vertical high-pressure pump reliably delivers ammonia at an operating temperature of -33 °C. The ammonia pump is installed outdoors in ATEX Zone 2; Zone 1 EX classification is maintained within the piping and pump.

These solutions meet the highest standards for operational safety, efficiency, and explosion protection.

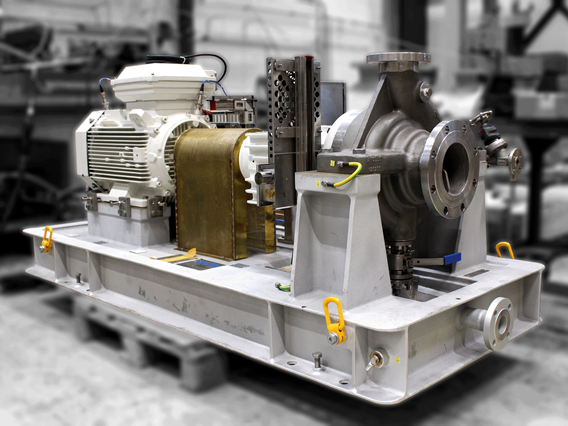

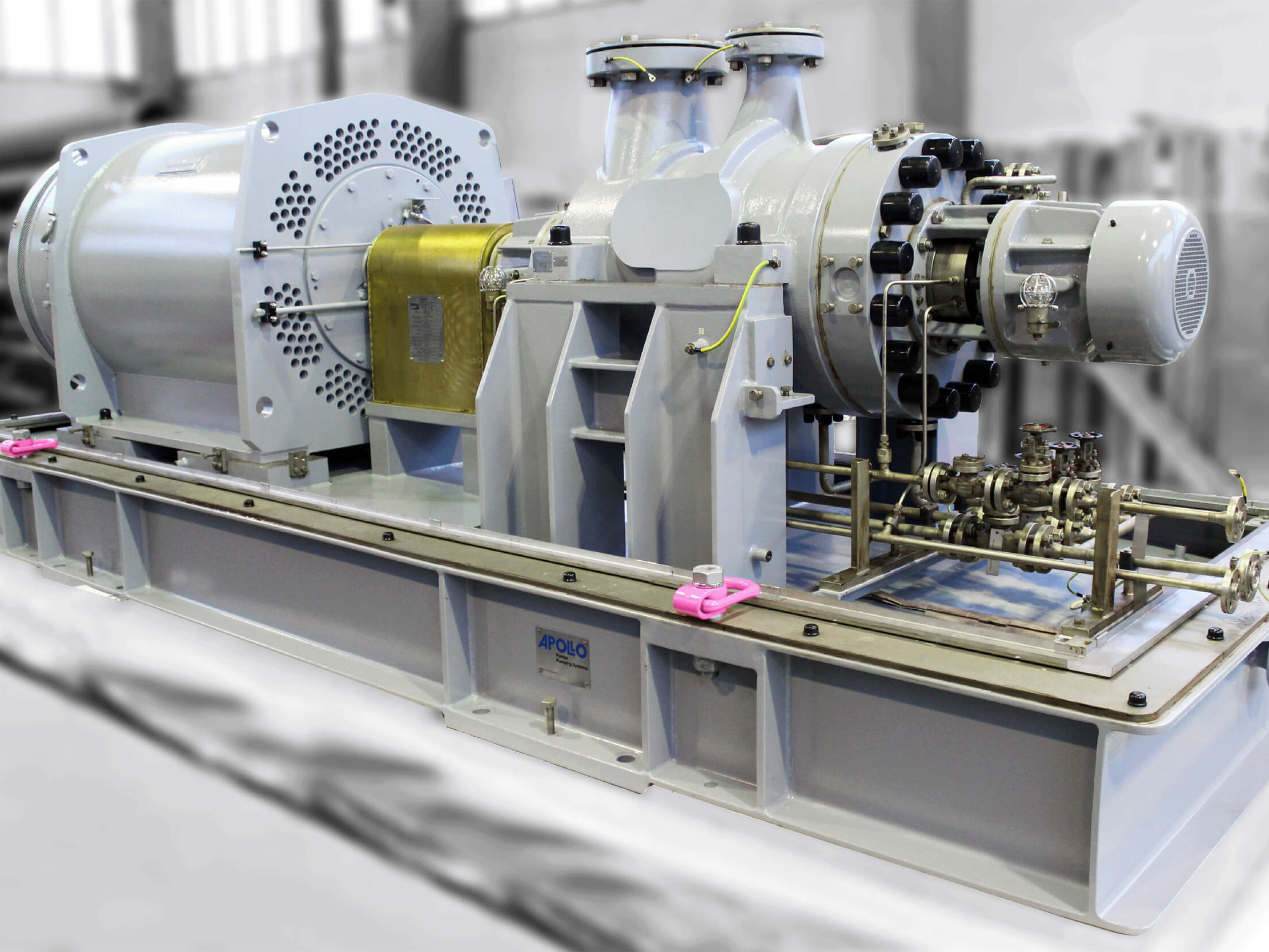

Process pump solutions for urea fertilizer production

For decades, Apollo Goessnitz GmbH has supplied reliable centrifugal pumps for the production of agricultural fertilizers.

The fertilizer manufacturer's product portfolio includes single-stage KRC end-suction pumps, multi-stage high-pressure pumps, side channel pumps, magnetically coupled pumps, and axially split centrifugal pumps.

Even demanding media, such as acidic condensate with dissolved gas, ammonium urea, ammonium nitrate urea, and ammonium carbonate solutions, are safely and efficiently pumped. These pumps meet the highest standards for operational safety, corrosion resistance, and energy efficiency, ensuring standard-compliant, economical, and sustainable fertilizer production.

*The above product overview is for reference purposes only and provides an overview of the basic range of products manufactured by Apollo. Additional pump types and systems, as well as detailed technical information and product/industry-specific classifications, are available from Apollo upon request.

Want to know more?

For over 160 years, Apollo Goessnitz GmbH has been a leading German manufacturer of industrial pumps and pump systems. As a European specialist in customized pump technology, we serve customers in the energy, chemical, and oil and gas industries around the globe. Our focus is on reliability, efficiency, and sustainable solutions.

![[Translate to English:]](/fileadmin/_processed_/f/7/csm_Standardpumpen_Seitenkanalpumpen_3a9d262bb8.jpg)