Midstream - high-performance pumps for transport and storage

Optimised pump solutions for pipelines, tank farms and transfer stations

In the midstream segment of the oil and gas industry, reliable pump systems are essential for safely and efficiently transporting and storing corrosive substances. Apollo Goessnitz GmbH offers a comprehensive portfolio of process pumps and system technology specifically designed to meet the challenging demands of pipelines, tank farms, and transfer stations.

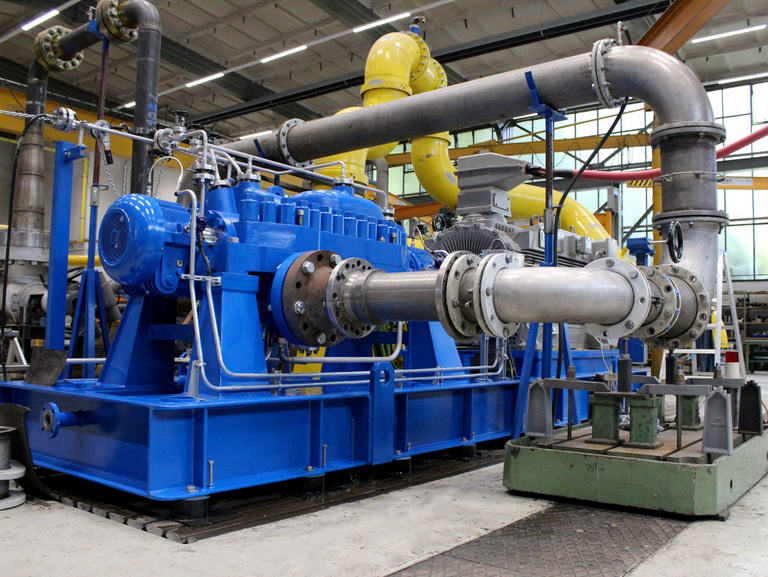

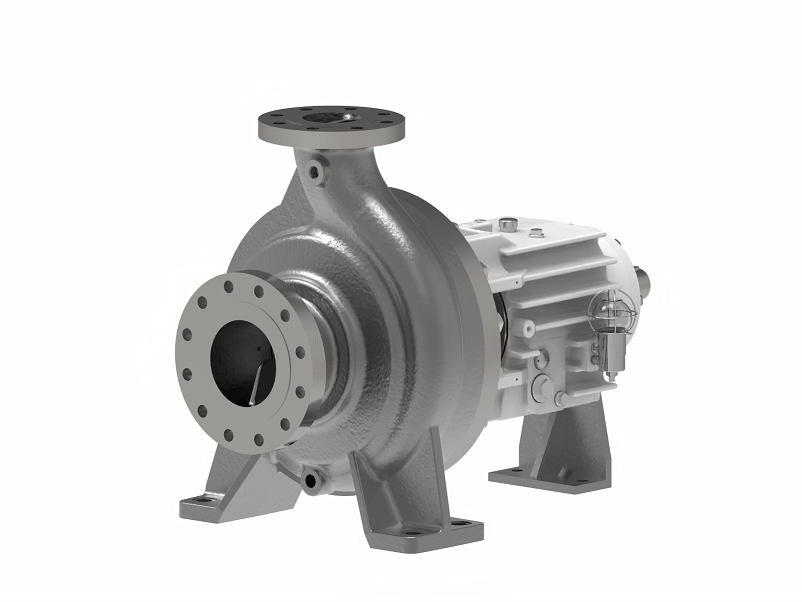

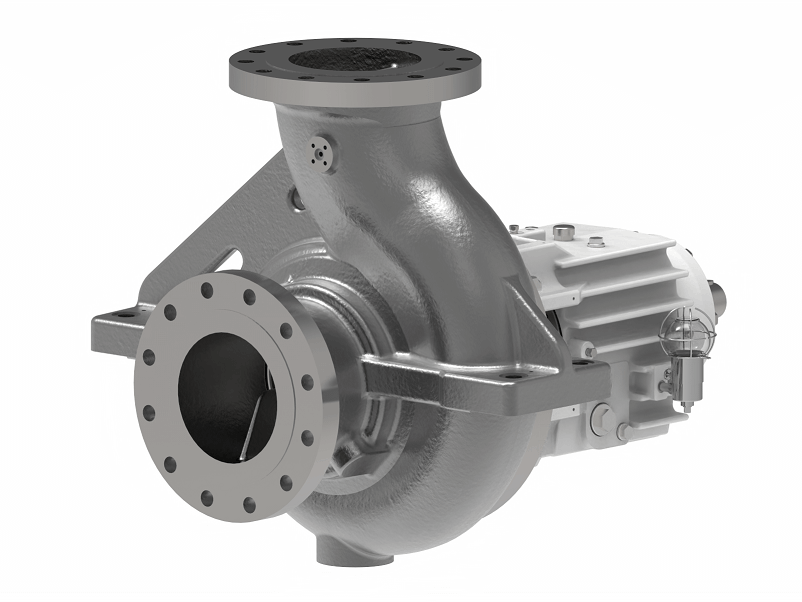

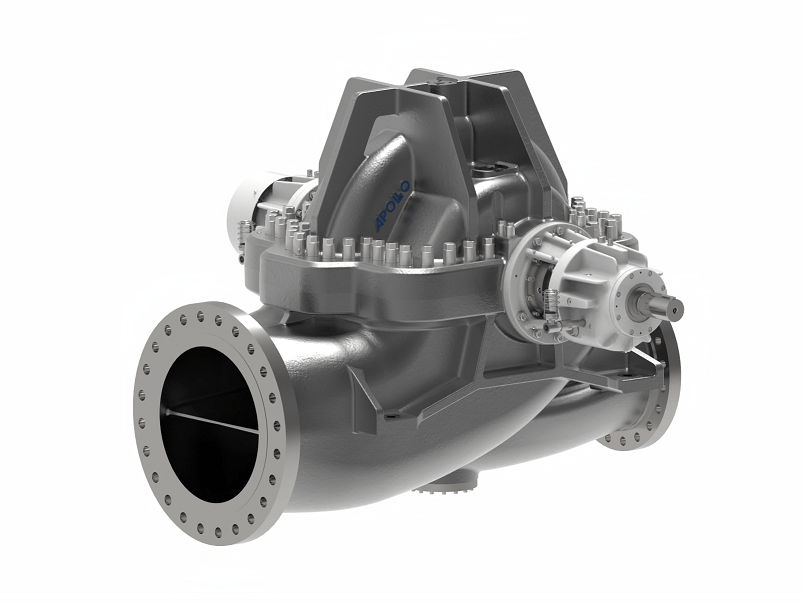

Booster pumps for pipeline applications

Apollo has manufactured AMG-150H/5 pumps for use in a booster pump station. These horizontally constructed, multi-stage, high-pressure pumps comply with the API 610 standard. These axially driven pumps can deliver 425 m³/h of Jet A1 and diesel to a height of 725 metres. The pumps' housing is made of S-6 material and is certified to ATEX category 2.

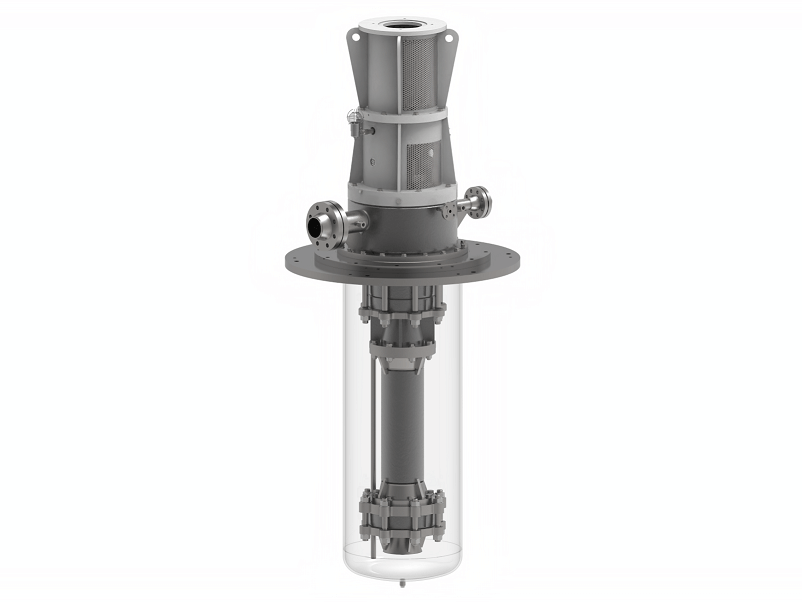

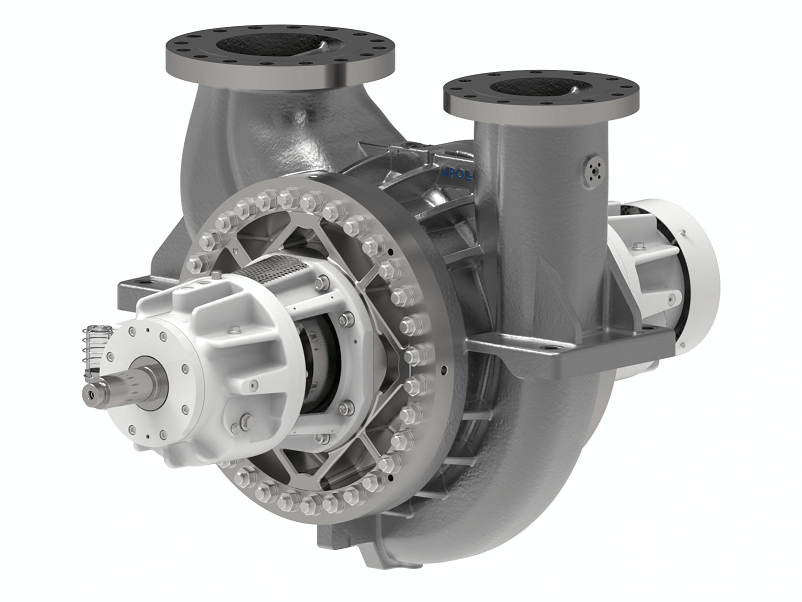

Can-type pumps for tank farms

The vertical, multi-stage high-pressure pumps of type GSTV were supplied for a Dutch tank farm. They are equipped with a sealing system for the "dry-running" version (Plan 76) and a lubricating oil system. The frequency converter and coupling have an ATEX certificate for zone 1 and potential equalisation for the same zone.

The three can-type pumps transport a propane and isobutane mixture at temperatures ranging from -19°C to 35°C. They were manufactured in accordance with API 610, Type VS6.

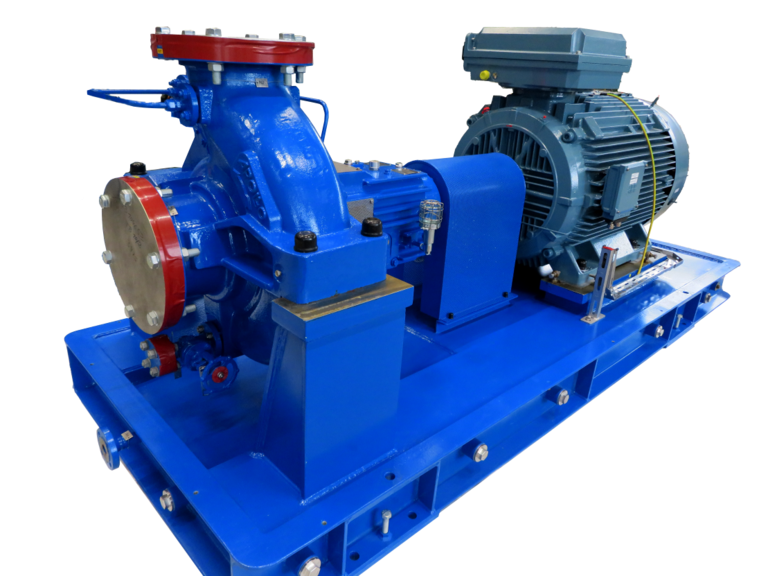

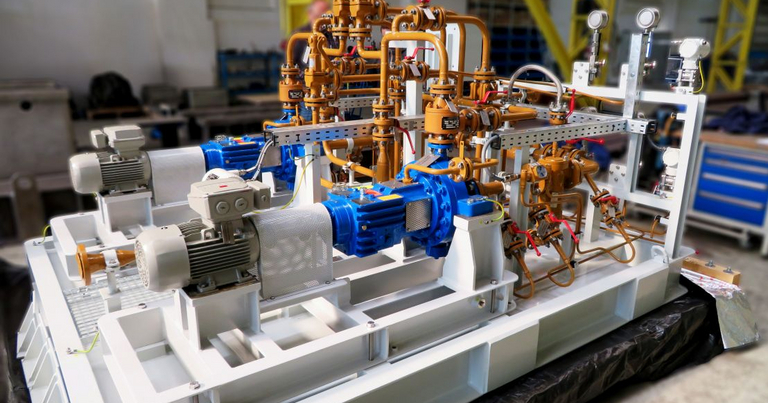

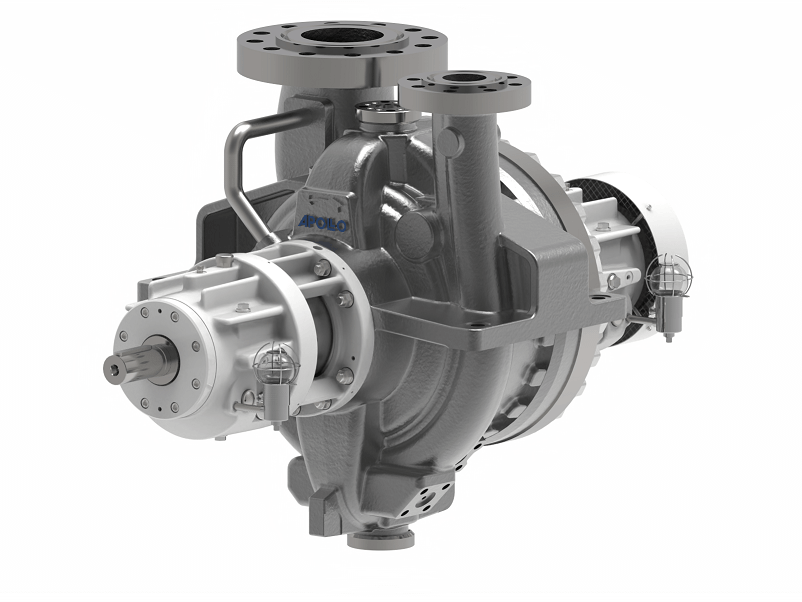

Transfer and forwarding station

Solutions for the safe storage and handling of media

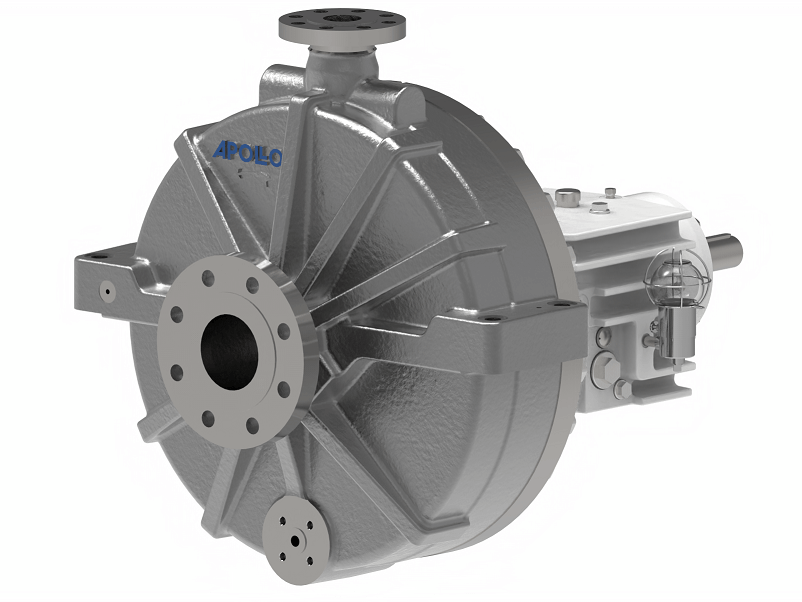

This is an example of an Apollo pumping system designed for the transfer and forwarding of fuel oil (diesel) and equipped with Apollo KRH centrifugal pumps. The pumps comply with the API 610 standard, type OH2, and guarantee reliable delivery under variable operating conditions thanks to their robust construction and optimised hydraulics. The system is characterised by high operational reliability, easy maintenance and a long service life.

Want to know more?

For over 160 years, Apollo Goessnitz GmbH has been a leading German manufacturer of industrial pumps and pump systems. As a European specialist in customized pump technology, we serve customers in the energy, chemical, and oil and gas industries around the globe. Our focus is on reliability, efficiency, and sustainable solutions.

Download Brochures

*The above product overview is for reference purposes only and provides an overview of the basic range of products manufactured by Apollo. Additional pump types and systems, as well as detailed technical information and product/industry-specific classifications, are available from Apollo upon request.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/a/csm_BB3-AMG_95c3692be4.jpg)

![[Translate to English:]](/fileadmin/_processed_/0/9/csm_BB5-TG-80M-15.20_a60e91da74.png)