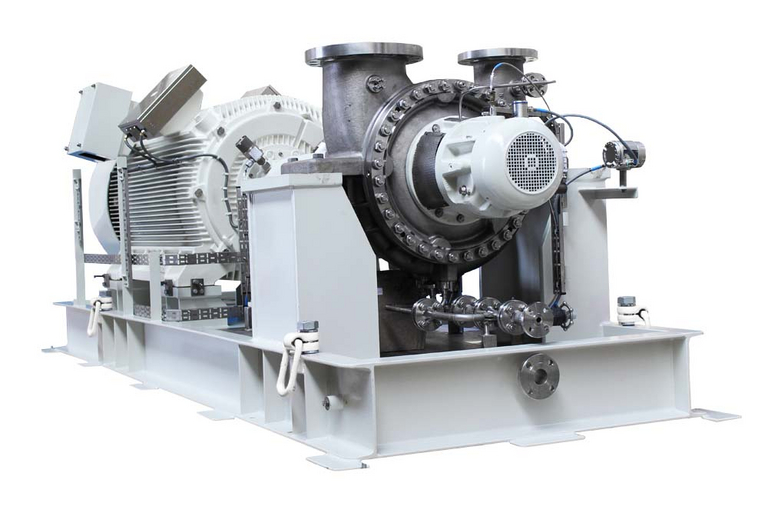

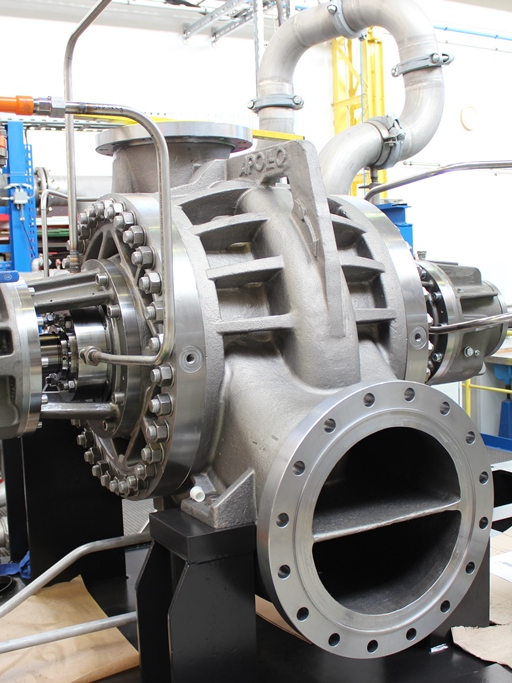

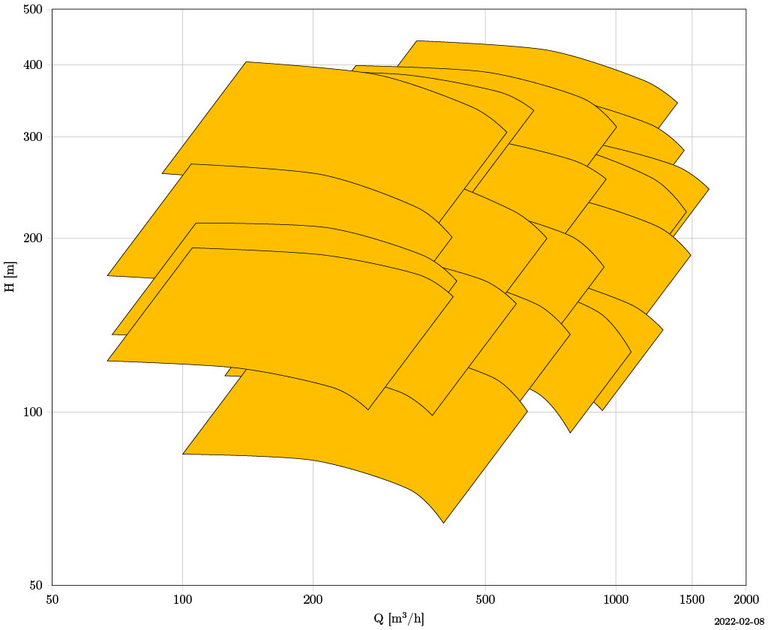

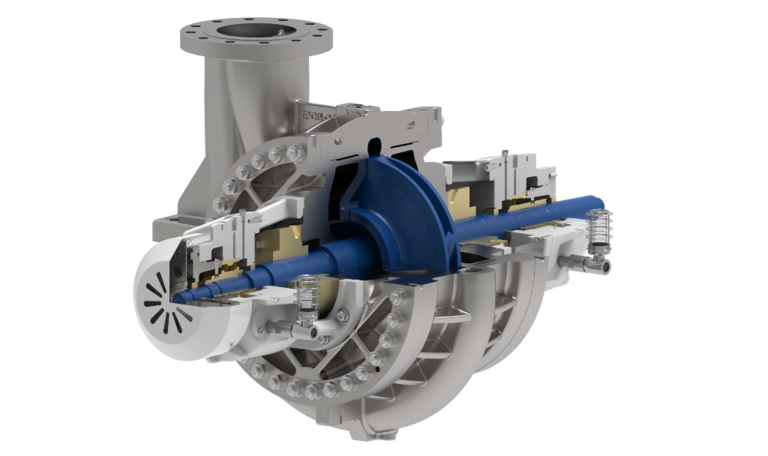

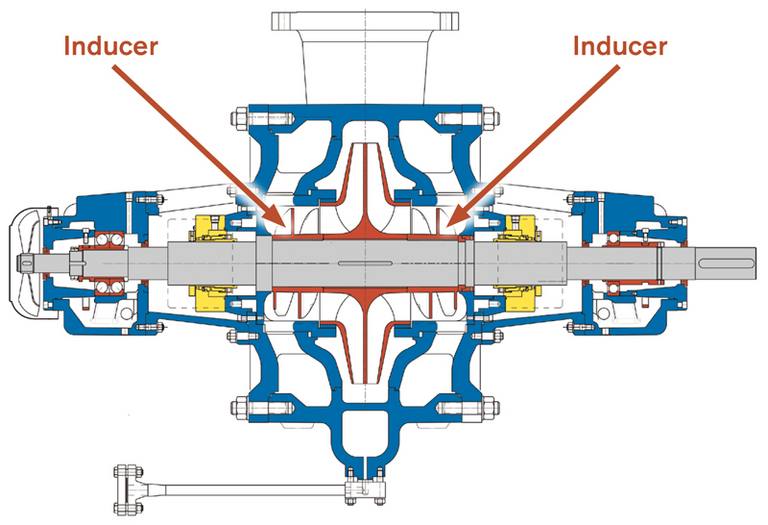

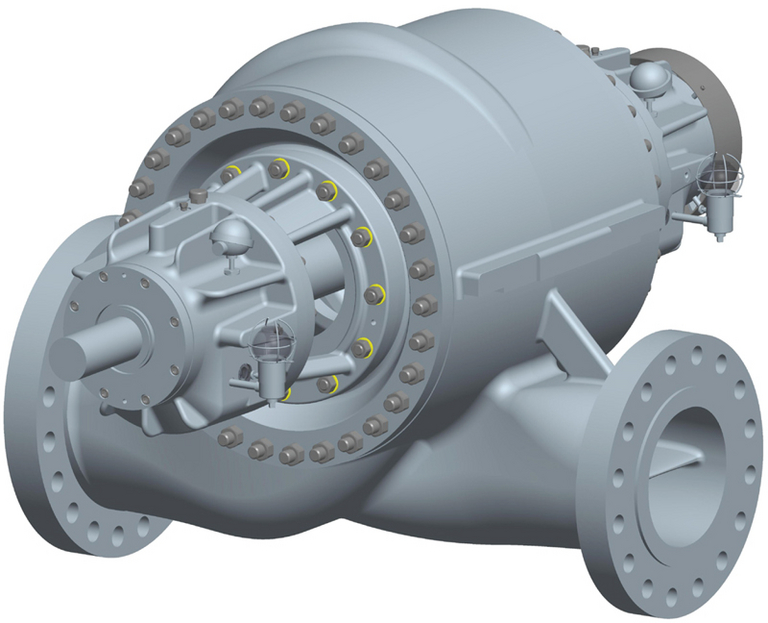

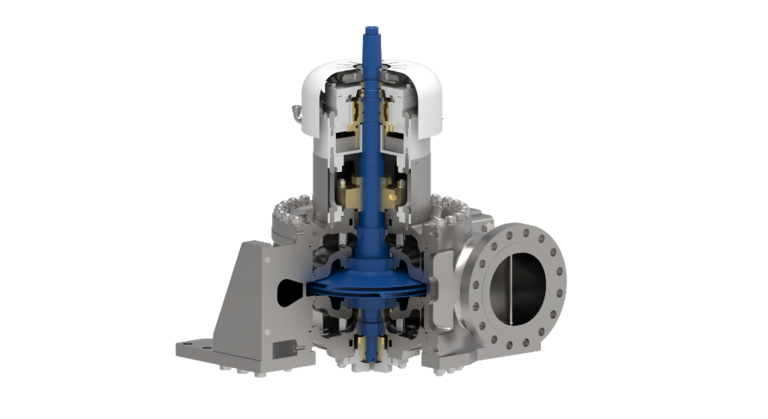

- single-stage, radial-split, volute casing pump of double-volute design

- double-flow impeller

- with bearings on both sides BB2

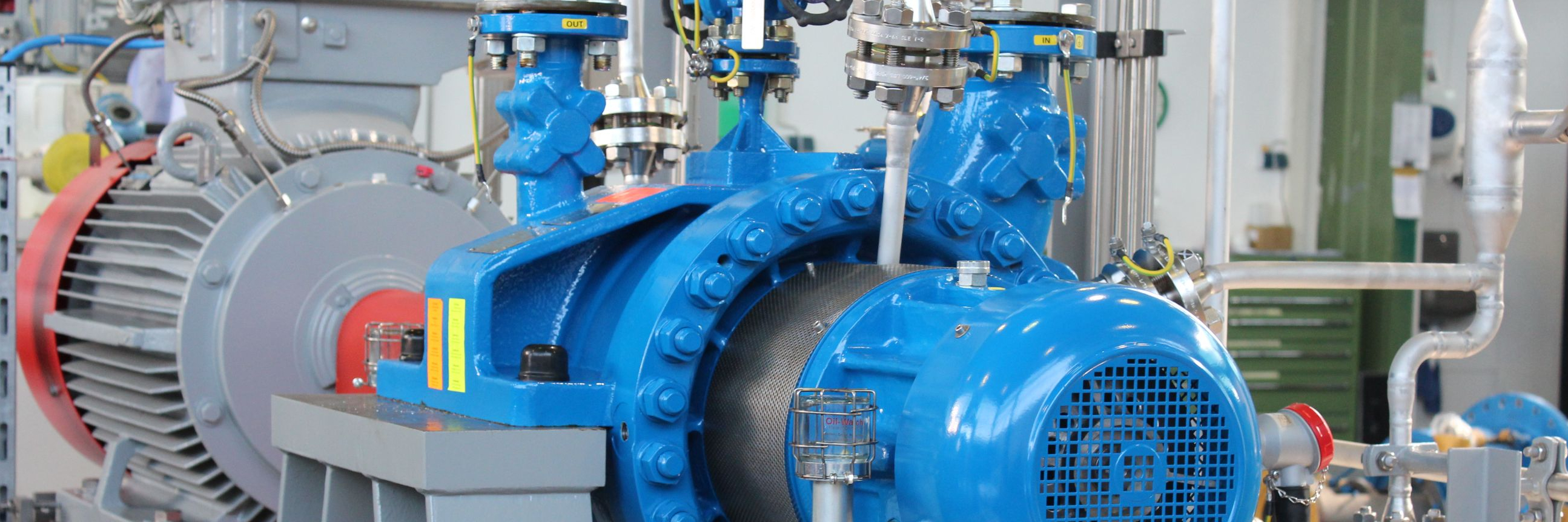

- centerline-supported

- variable nozzle arrangement possible

- internal and external sealing by means of helical wound metal/graphite seal

- a design with wear plate is possible

- ZPRV as vertical version

Want to know more?

Apollo Goessnitz GmbH - European pump manufacturer from Germany. We stand for quality and innovative solutions in customised pump technology.