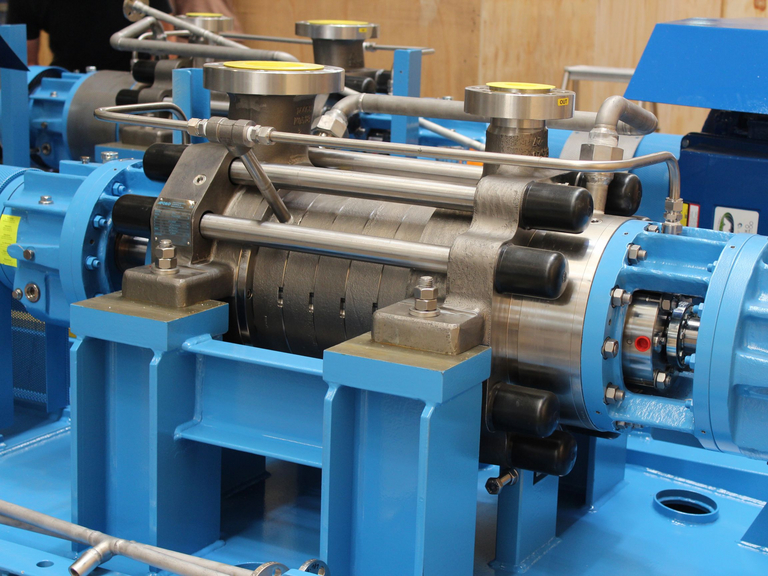

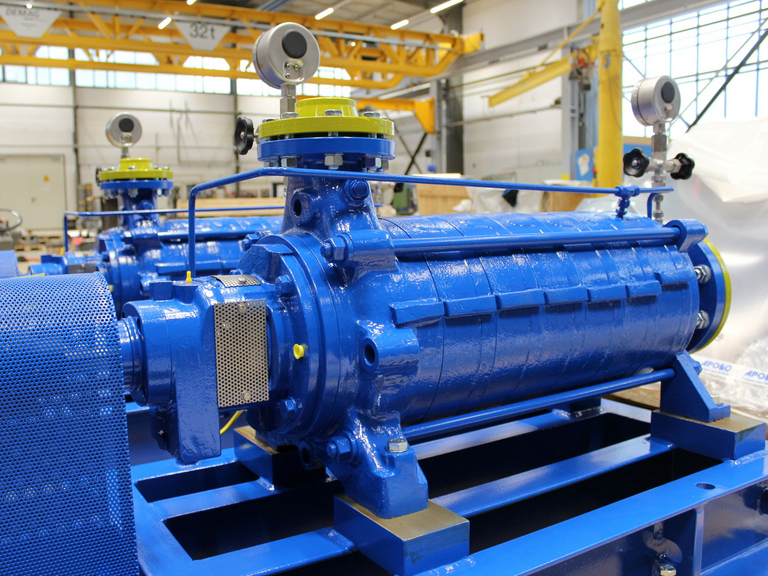

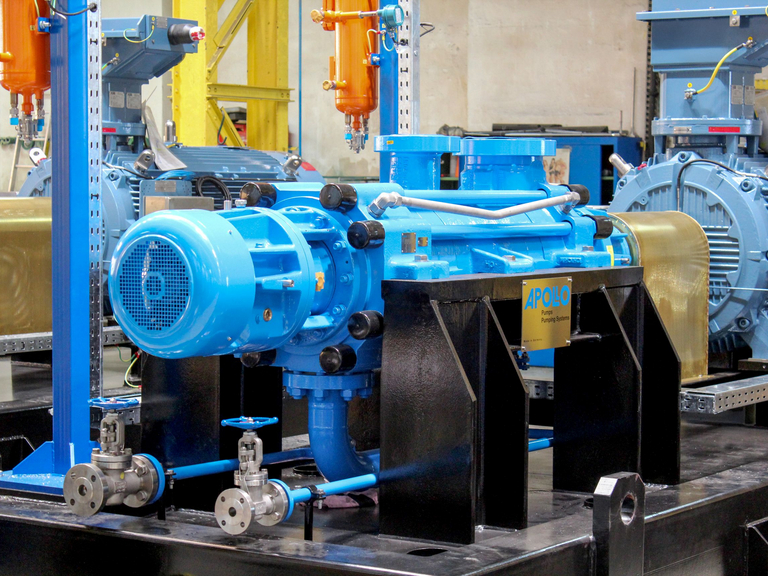

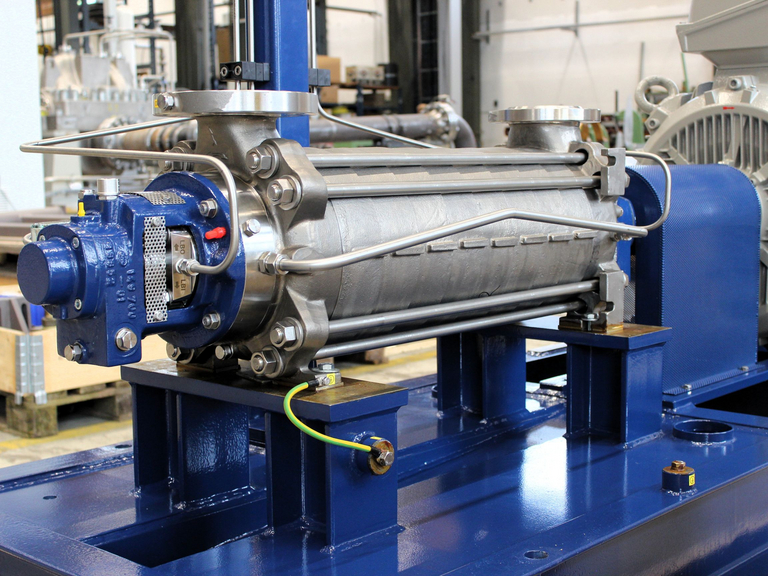

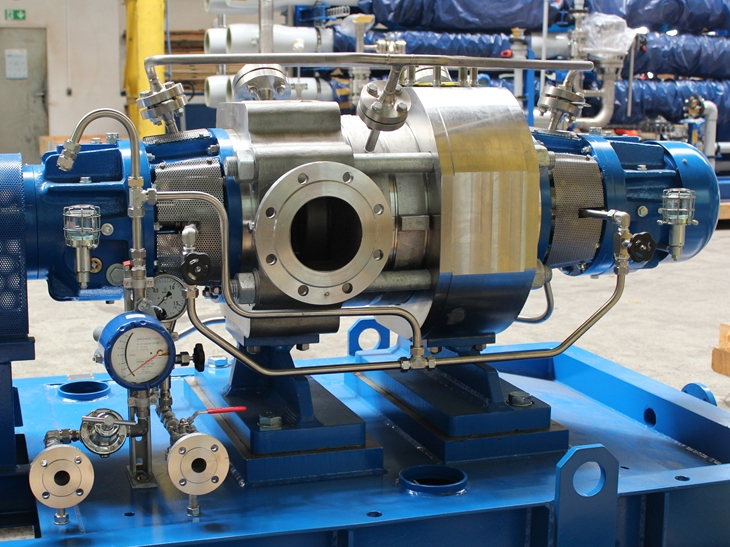

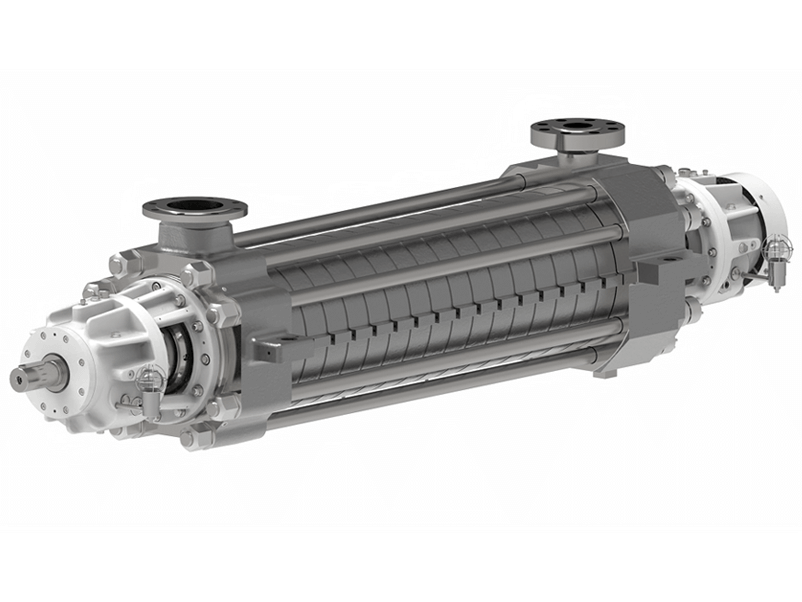

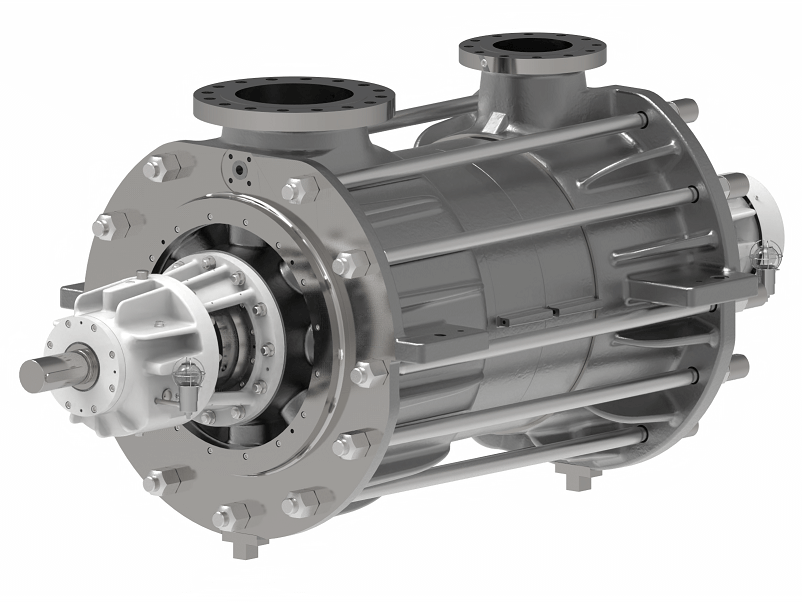

Horizontal, multistage pump of ring-section design – high-pressure centrifugal pumps for demanding industrial and power plant applications

Horizontal high-pressure centrifugal pumps with a ring-section design are the best option when very high delivery pressures are required for moderate to medium flow rates. These pumps consist of several stages arranged in series and mounted axially, one behind the other, as individual 'sections' on a common shaft. The sections are braced together using tie rods to form a high-pressure-resistant pressure shell. Each stage increases the pressure further while the volume flow remains almost constant. This makes them ideal for processes requiring a continuous and stable pressure increase.

In the industrial standard and the API 610 environment, these horizontal high-pressure pumps are classified as type BB4. They are multi-stage, radially split and modular in design, and are developed for extreme pressures, long running times and demanding operating conditions. Thanks to their modular housing design, the delivery head can be adjusted flexibly via the number of stages, without changing the basic design.

Apollo Gößnitz develops multistage pumps with a standard design and an API 610-compliant design for use in power plants, the oil and gas industry, chemical processes and demanding high-pressure applications. The combination of high-pressure resistance, a modular design and double-sided bearings enables reliable, continuous operation under high-temperature and high-pressure conditions. The system can even be used with critical process media or high plant requirements.

Advantages of multi-stage ring-section pump:

- Hydraulically balanced design in terms of application range, efficiency, and rotor dynamics

- Modular design for optimum adaptation to customer requirements and low operating costs

- API 610 BB4-compliant design for extreme industrial requirements

- High variability thanks to flexible positioning of suction and discharge nozzel

- Efficient pressure increase at constant volume flow

Typical applications:

- Power Plants: Boiler feed and feed water pumps

- Industry: Process water, cleaning systems, pressure boosting

- Oil & Gas: Pipeline pressure boosting, conveying processes, drilling applications

- water management: Long-distance transport, pressure boosting, water treatment

- Chemistry & Petrochemistry: High-pressure process fluids, corrosive media

Want to know more?

Apollo Goessnitz GmbH - European pump manufacturer from Germany. We stand for quality and innovative solutions in customised pump technology.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/7/csm_GH_e98376d2df.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/inhalte/bilder/03_pumpen/GM/GM_mehrstufige-Pumpe.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/5/csm_GMZ_e4ee956633.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/b/csm_GL_7b732807dd.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/a/e/csm_GLA_dedff434f0.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/inhalte/bilder/03_pumpen/GLZ/GLZ_mehrstufige-Pumpe.jpg)