Vertical volute casing pumps – Reliable sump and tank pumps for demanding process liquids

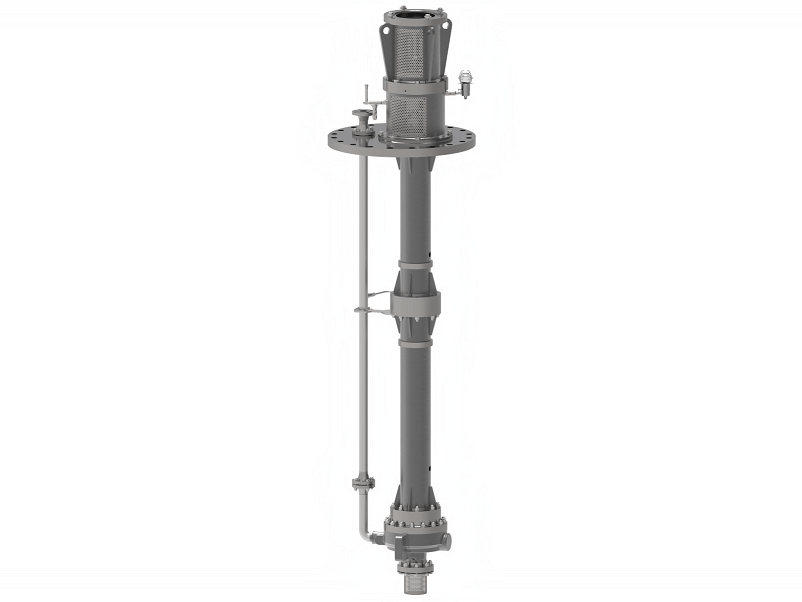

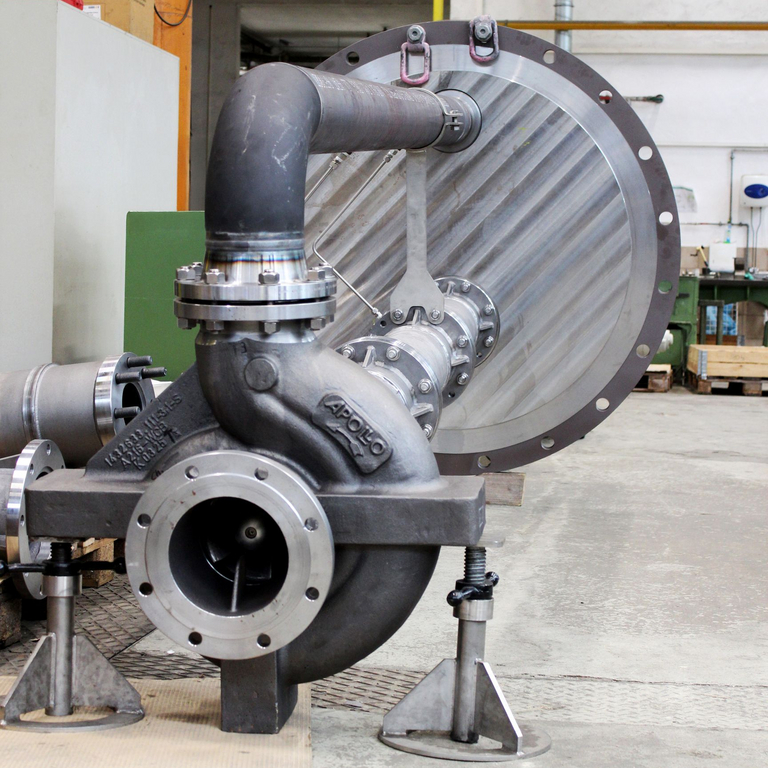

Apollo Gößnitz vertical spiral casing pumps are robust centrifugal pumps. The hydraulic section (consisting of the impeller and volute casing) is submerged vertically in a sump, shaft or tank, while the motor and bearings are mounted above in a dry location. This design allows for the safe pumping of liquids directly from collection tanks or process containers, even when the liquids are difficult, hot or dirty.

Standard versions are manufactured in accordance with ISO standards and are available in single-stage configurations with short or extended shafts. For industrial applications with specific safety and material requirements, Apollo also offers vertical pumps in accordance with API 610 VS4, including single-stage end-suction sump pumps with extended shafts. These allow the hydraulic part to be immersed deep into the medium and meet the highest standards in the oil, gas, chemical and energy industries.

VS4 pumps are the preferred solution when media must be conveyed directly from a pit rather than being sucked in. They are highly reliable, require little maintenance, and are suitable for aggressive or corrosive liquids.

Advantages of vertical volute casing pumps

- Vertical design: Pump section is submerged in the fluid, motor keeps dry

- Volute casing for high hydraulic efficiency and robust construction

- Long or short shaft configuration, depending on installation and tank depth

- API 610 VS4 design

- Resistant to high temperatures, contamination, and aggressive fluids

Typical areas of application

- Refineries & Petrochemicals: Sump fluids, leakage containers, process water

- Power plants & energy facilities: Drainage, container emptying, hot liquids

- chemical industry: Acids, solvents, corrosive process fluids

- Environmental & Process Engineering: Wastewater, rainwater, and dirty water pumping

- Mining & Industry: Drainage and process fluids

Want to know more?

Apollo Goessnitz GmbH - European pump manufacturer from Germany. We stand for quality and innovative solutions in customised pump technology.