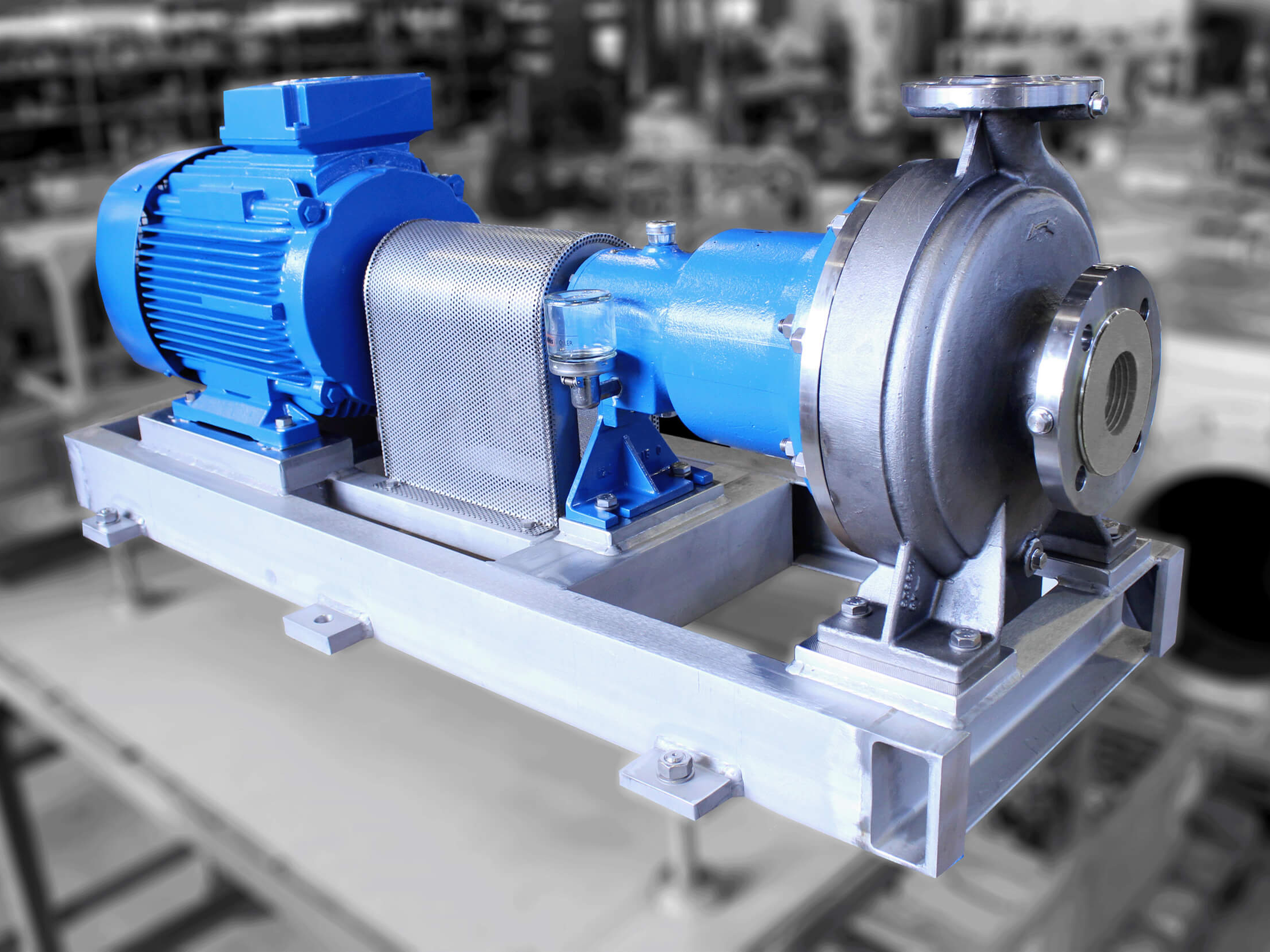

Chemical pumps are continuously exposed to extreme operating conditions. Pumping aggressive, corrosive, or potentially explosive media requires materials and designs that guarantee maximum durability and reliability. These pumps must handle these stresses safely throughout their entire service life while strictly complying with all relevant safety and standard requirements.

Apollo offers technically optimized centrifugal pumps and system technology for fertilizer production, chemical production, and petrochemical processes. These pumps can be flexibly and precisely adapted to individual requirements.

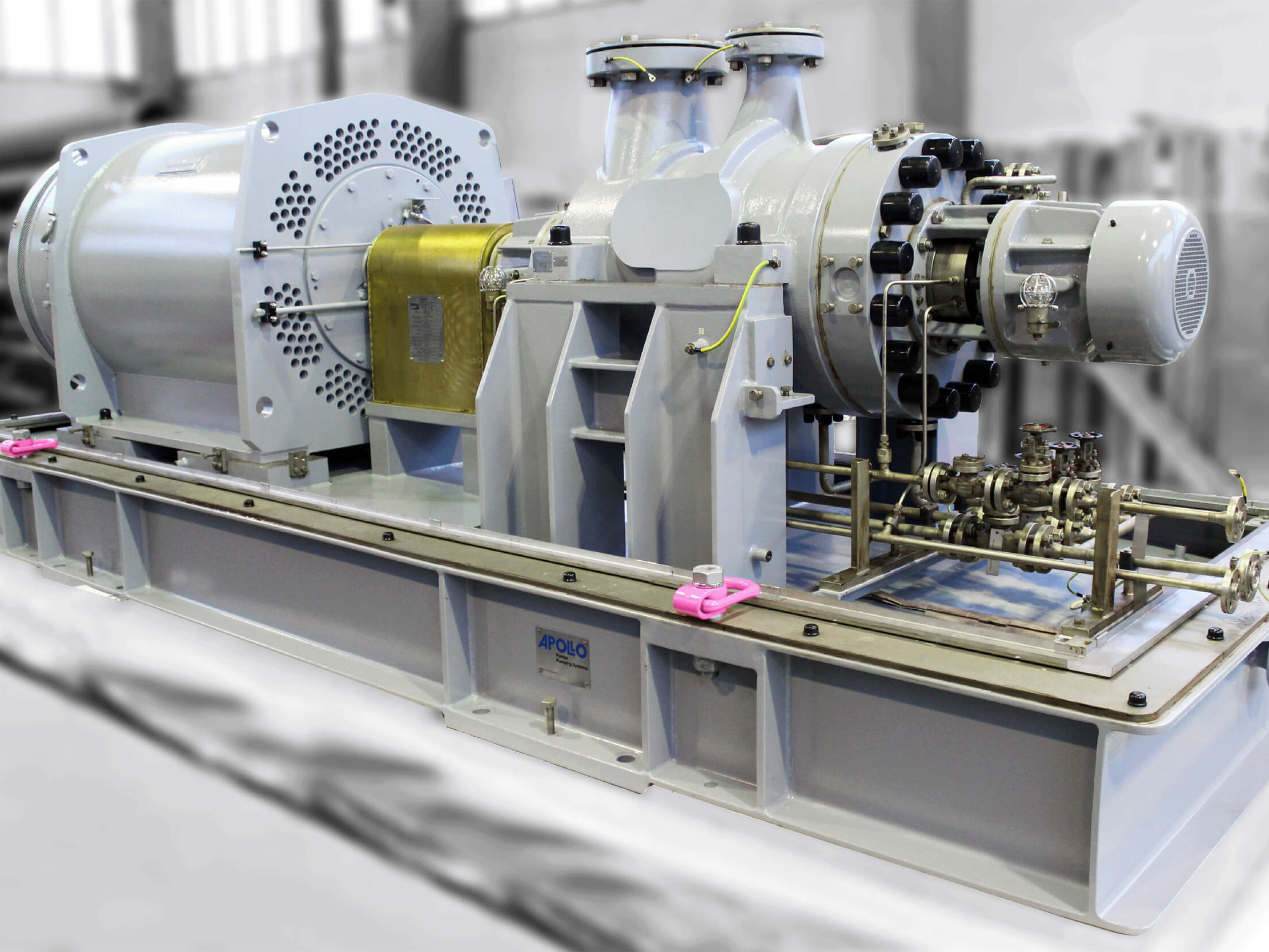

SRU nanofiltration system and high-pressure pump system

Innovative solutions for green chemical technologies

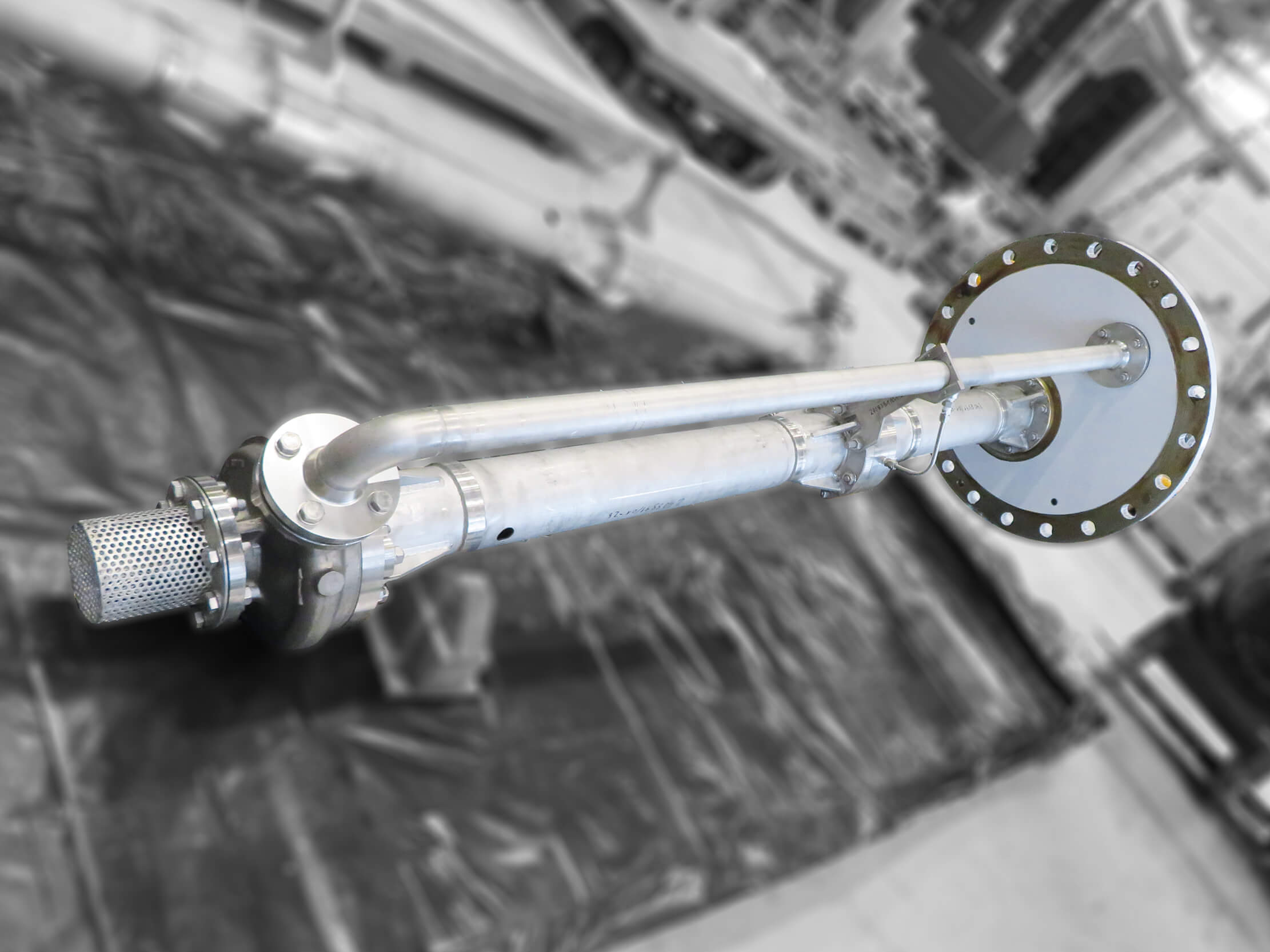

Apollo developed and manufactured a ready-to-connect nanofiltration desulfurization system for a leading chemical company. The system includes fully pre-assembled subsystems with integrated valves and measurement technology, as well as a high-pressure pump skid. The multi-stage HPB high-pressure pump, manufactured in accordance with API 610 and BB4, ensures the reliable delivery of 100 m³/h of aggressive brine.

Due to the aggressive nature of the brine, the pump was designed with duplex material. The unit is equipped with titanium fittings and PN63 piping made of grade 2 titanium to ensure maximum corrosion resistance and operational safety. Apollo carried out all manufacturing and assembly work, including inert gas welding.

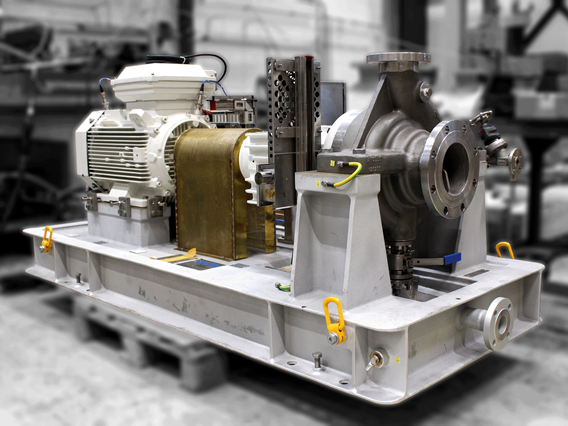

Boiler feed pump for the production of speciality chemical products

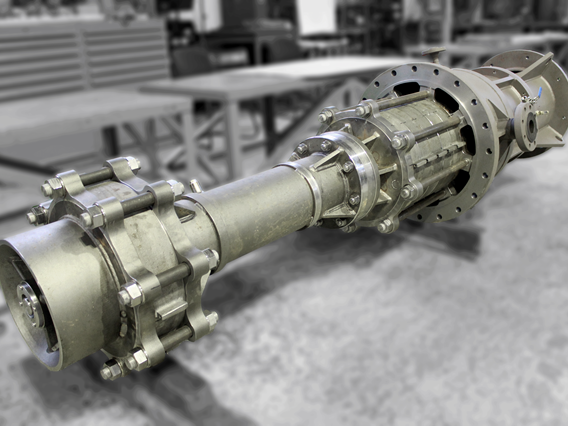

Apollo supplied a 17-stage HPD series pump with a ring-section design to a chemical plant that manufactures special additives for the plastics, paper, and paint industries, as well as special chemical products for the ceramics, refractory, polishing agent, and agricultural industries.

This process pump is designed to convey boiler feed water at a temperature of 140 °C and a delivery head of 2,150 metres.

The pump unit meets the highest reliability, efficiency and operational safety requirements, ensuring compliance with relevant norms and quality standards in demanding chemical environments.

Can-type pumps for the production of polypropylene

The Apollo HPTV high-pressure pumps, which comply with API 610 VS6, were designed to meet the requirements of a polypropylene production plant.

These vertical, multi-stage feed pumps reliably and efficiently convey propylene at a temperature of 90 °C. The S-6 housing material, which complies with API standards, ensures high resistance to process conditions and contributes to the operational safety of the plant.

Want to know more?

For over 160 years, Apollo Goessnitz GmbH has been a leading German manufacturer of industrial pumps and pump systems. As a European specialist in customized pump technology, we serve customers in the energy, chemical, and oil and gas industries around the globe. Our focus is on reliability, efficiency, and sustainable solutions.

Download Brochures

*The above product overview is for reference purposes only and provides an overview of the basic range of products manufactured by Apollo. Additional pump types and systems, as well as detailed technical information and product/industry-specific classifications, are available from Apollo upon request.

![[Translate to English:]](/fileadmin/_processed_/f/7/csm_Standardpumpen_Seitenkanalpumpen_3a9d262bb8.jpg)