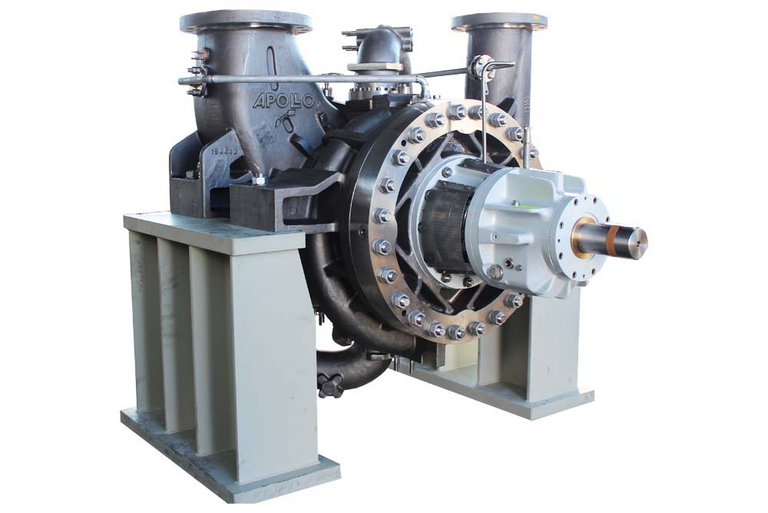

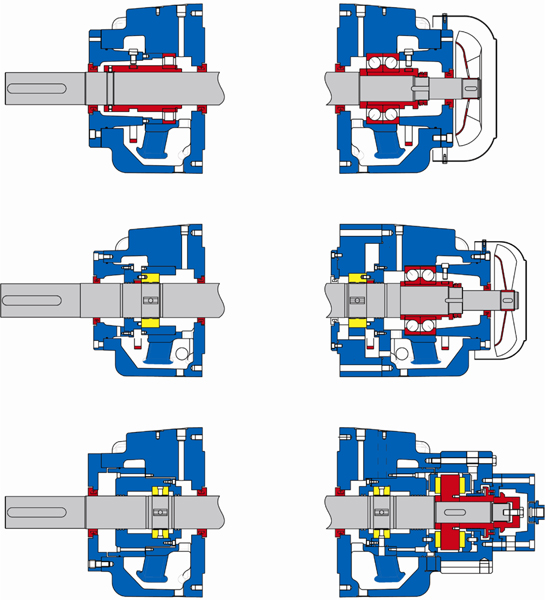

- Standard Version

Radial bearings: antifriction bearings

Axial bearings: antifriction bearings

Ring oil lubrication

- Variant

Radial bearings: slide bearings

Axial bearings: antifriction bearings

Ring oil lubrication

- Variant

Radial bearings: slide bearings

Axial bearings: slide bearings

Pressure oil lubrication

Want to know more?

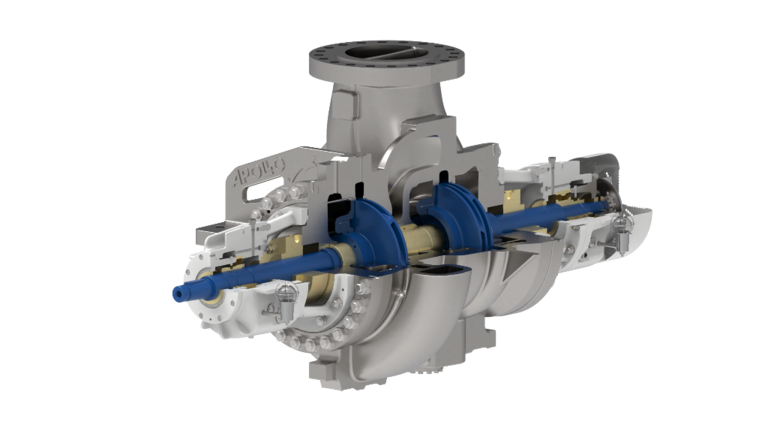

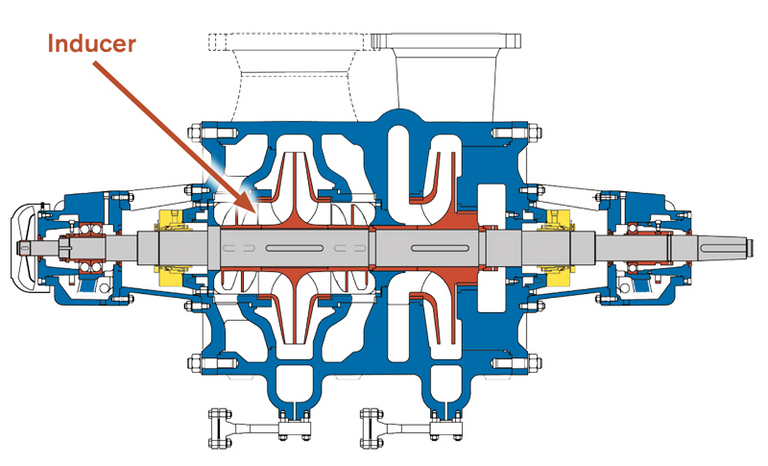

Apollo Goessnitz GmbH - European pump manufacturer from Germany. We stand for quality and innovative solutions in customised pump technology.