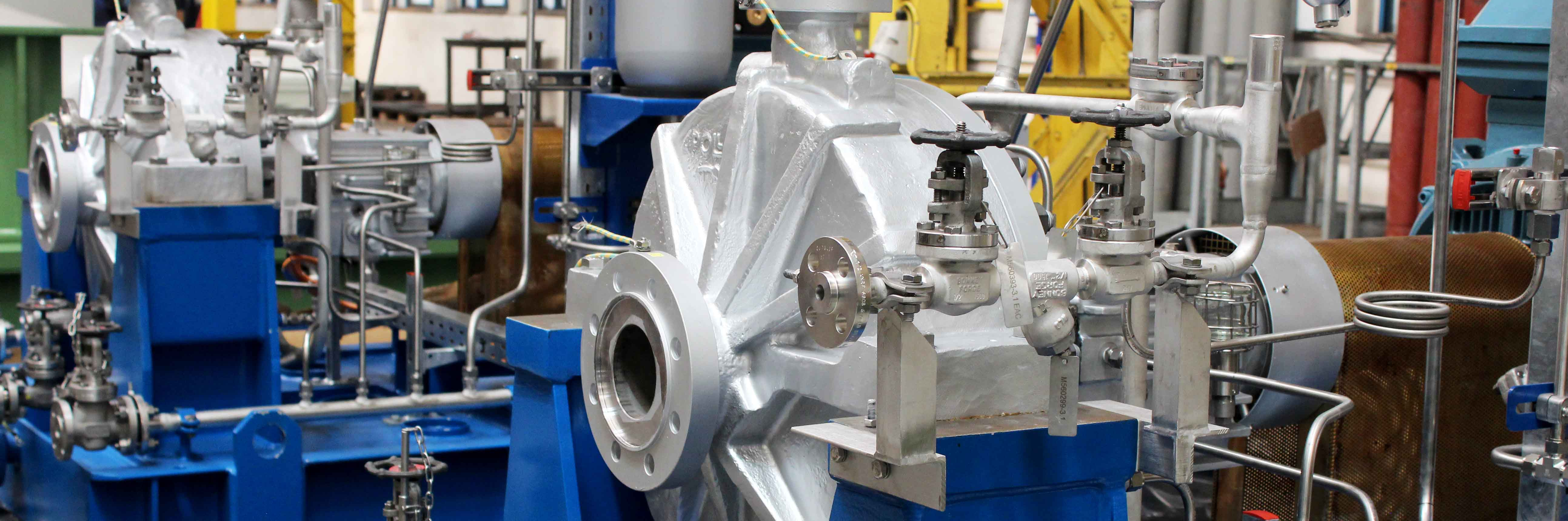

Our range of single-stage centrifugal pumps, including the OH1, OH2 and OH3 models, meets the high standards required by the process industry and is ideal for a variety of applications.

What are single-stage process pumps?

They are centrifugal pumps equipped with a single impeller. They are designed for continuous liquid transport in various industrial processes. Their design ensures high efficiency and reliability.

Types of single-stage OH centrifugal pumps (overhung)

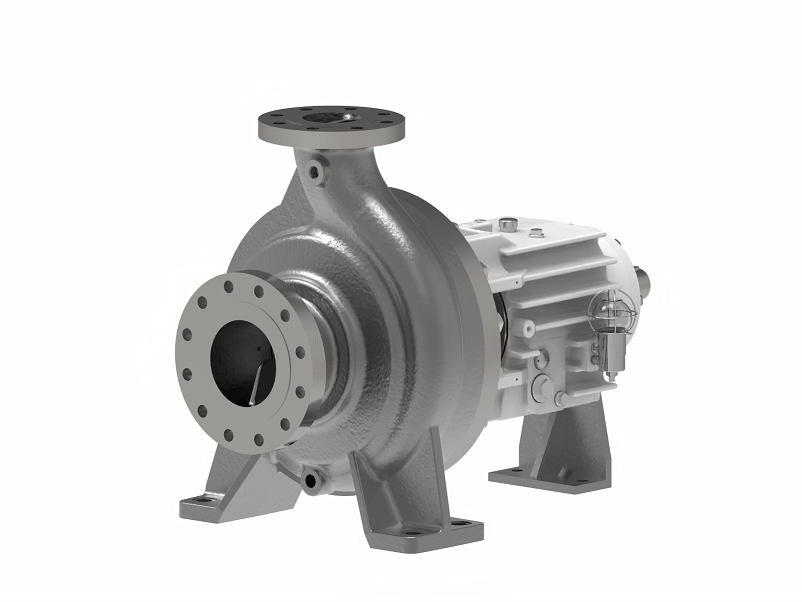

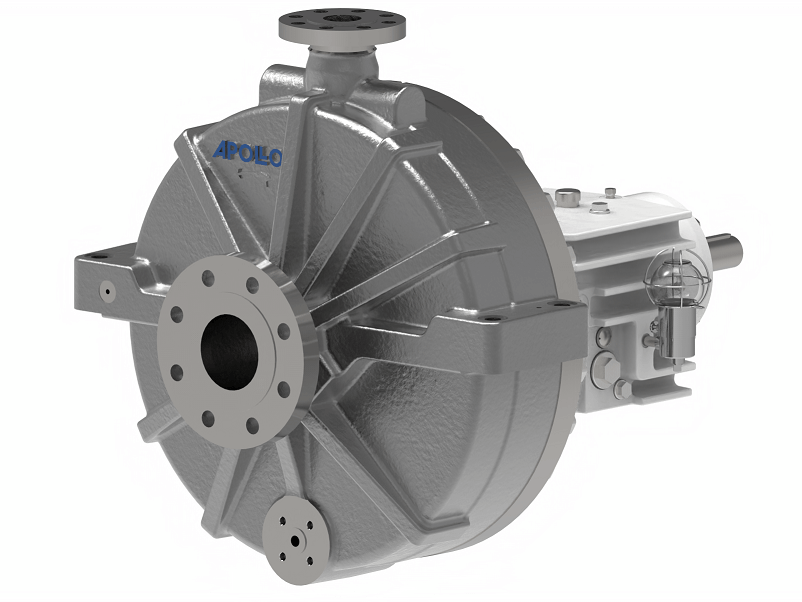

The OH1 is a powerful, single-stage, single-flow, normal-priming end suction pump. Their horizontal design and oil-lubricated bearings ensure high reliability and efficiency. Thanks to their wide range of extension sizes, they offer comprehensive performance capabilities that can be flexibly adapted to your specific requirements.

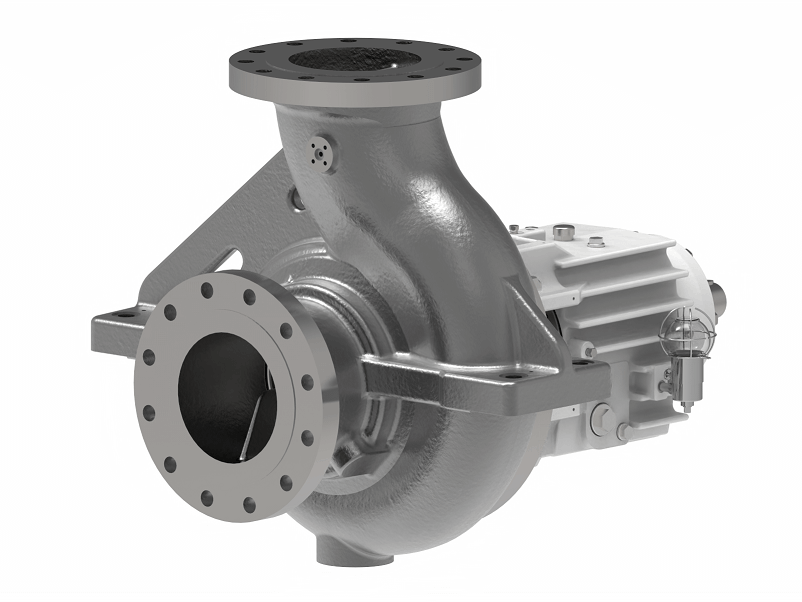

OH2 pumps are characterised by their horizontal design, which ensures a robust construction. Designed for a wide range of applications, they can easily meet specific requirements. They feature a horizontal, single-stage, radially split design and are available in special versions for applications with low flow rates and high delivery heads. These versions are equipped with either a semi-open or closed impeller.

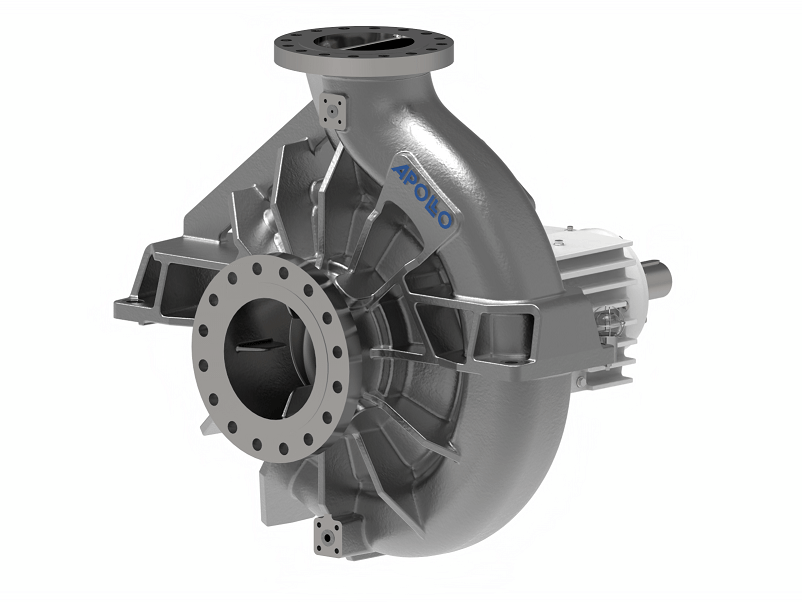

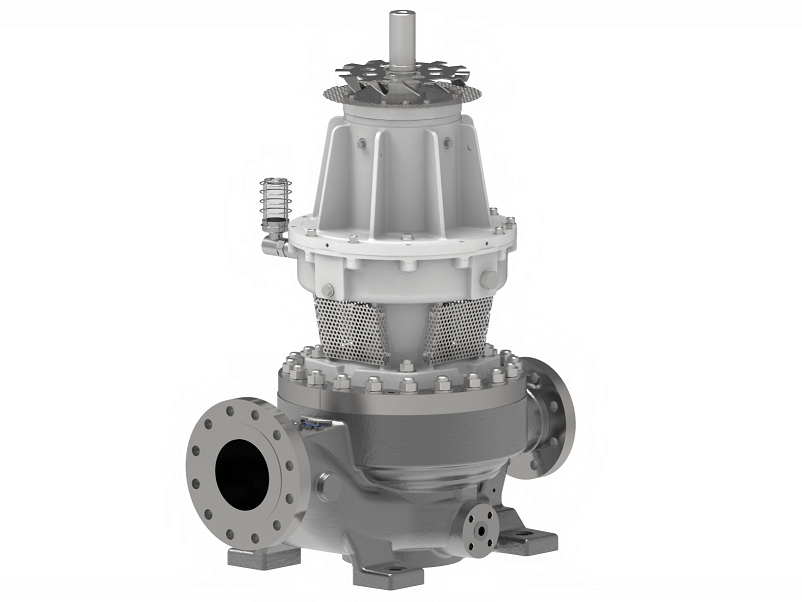

OH3 pumps are specialised variants that meet the stringent requirements of the API 610 standard. As vertical, single-stage, radially split, high-performance, inline process pumps, they are characterised by minimal installation space requirements and low transport weight. These features make them ideal for demanding applications in the offshore industry, refining processes, and other challenging environments.

Typical applications of OH Pumps

- Refineries and petrochemical processing plants

- Hot water applications

- Offshore technology

- Power plant technology

- Gas processing plants

- Seawater desalination stations

- Chemical industries and process engineering

- General industry and building services engineering

These versatile pump systems are indispensable in many industries thanks to their efficient and reliable performance in a wide range of applications.

FAQs about Single-Stage Process Pumps (API 610 OH1, OH2, OH3)

Each pump variant has its own specific advantages: The OH1 impresses with its simple, robust design and high reliability, while the OH2 is ideal for more demanding conditions. The OH3, on the other hand, enables space-saving installation thanks to its vertical (in-line) design. To optimise efficiency and performance, the right pump should be chosen based on the requirements of the application.

The OH1, OH2 and OH3 pumps are characterised by their flexibility and high performance, making them the ideal solution for efficiently pumping a wide variety of media. Designed for use in numerous industries, including energy production, oil and gas, offshore operations, and the chemical and petrochemical sectors, they are highly versatile. They are also successfully used in water treatment and refineries.

Our pumps are available in a wide range of corrosion-resistant materials, including cast iron, cast steel, stainless steel, austenitic steel, duplex steel and super duplex steel, as well as renowned alloys such as titanium and Inconel. We also offer special alloys that comply with the strict NORSOK and NACE specifications, enabling us to meet the specific requirements of your application optimally.

Our pumps have a user-friendly design that makes them easy to inspect and maintain. Regular maintenance and inspections can significantly extend the service life and efficiency of your pumps. If you have any questions or would like to arrange servicing, please contact us. Simply email our service department at service (at) apollo-goessnitz.de.

Should you require information regarding the various API 610 pump types, please refer to the website or contact sales (at) apollo-goessnitz.de directly.