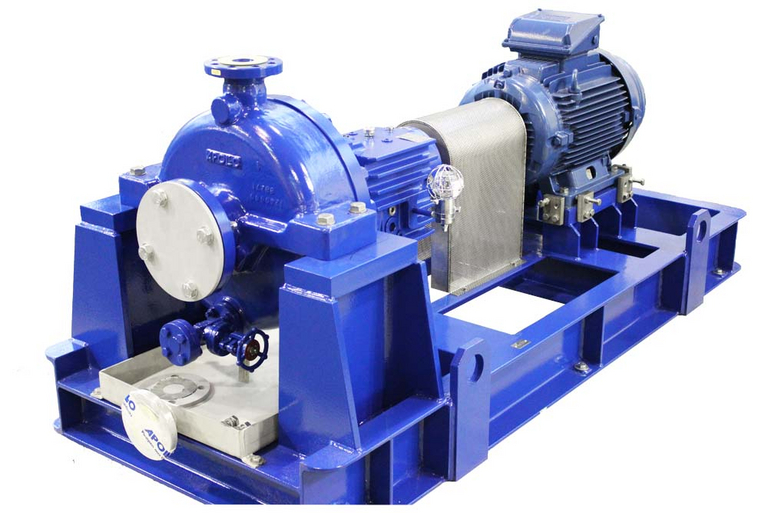

The pumps of type KRHL are applied in processing plants where complicated processing problems of liquid pumping have to be solved. Clean and slightly contaminated, cold and hot, chemically neutral or aggressive liquids can be pumped with these pumps.

- High-temperature applications

- Petrochemical Plants, Refineries

- Chemical Industry/Process Engineering

- Power Plants

- Environmental and Offshore Engineering

- Treatment Plants for Mineral Oil Systems, etc.