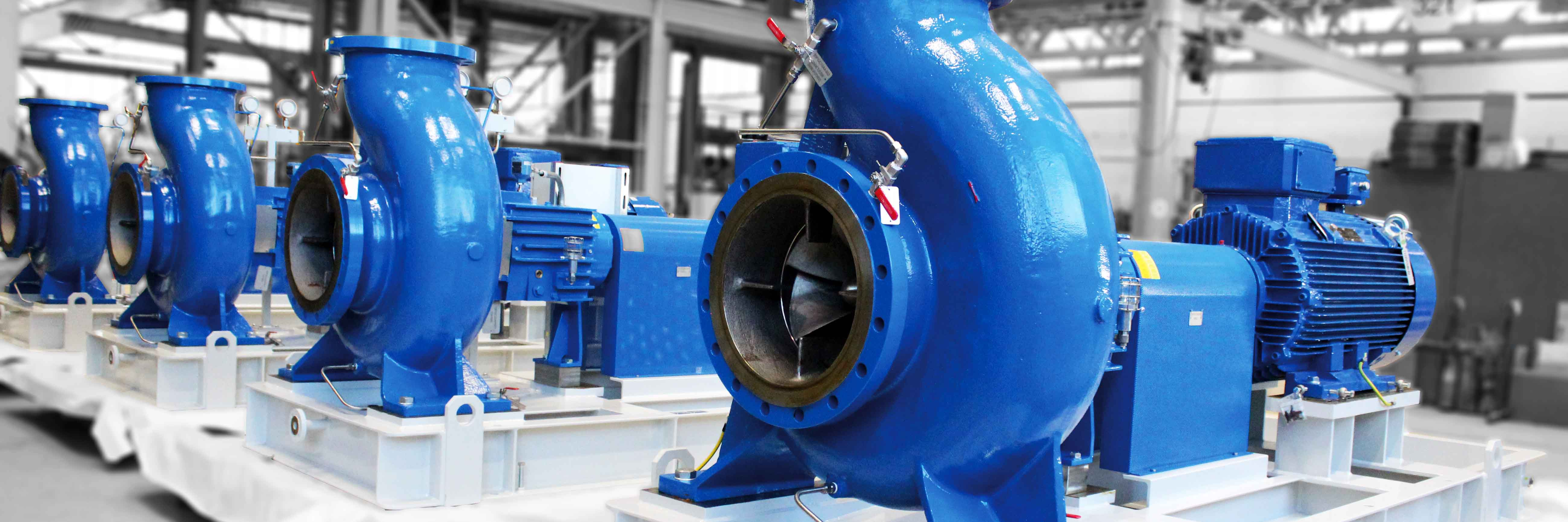

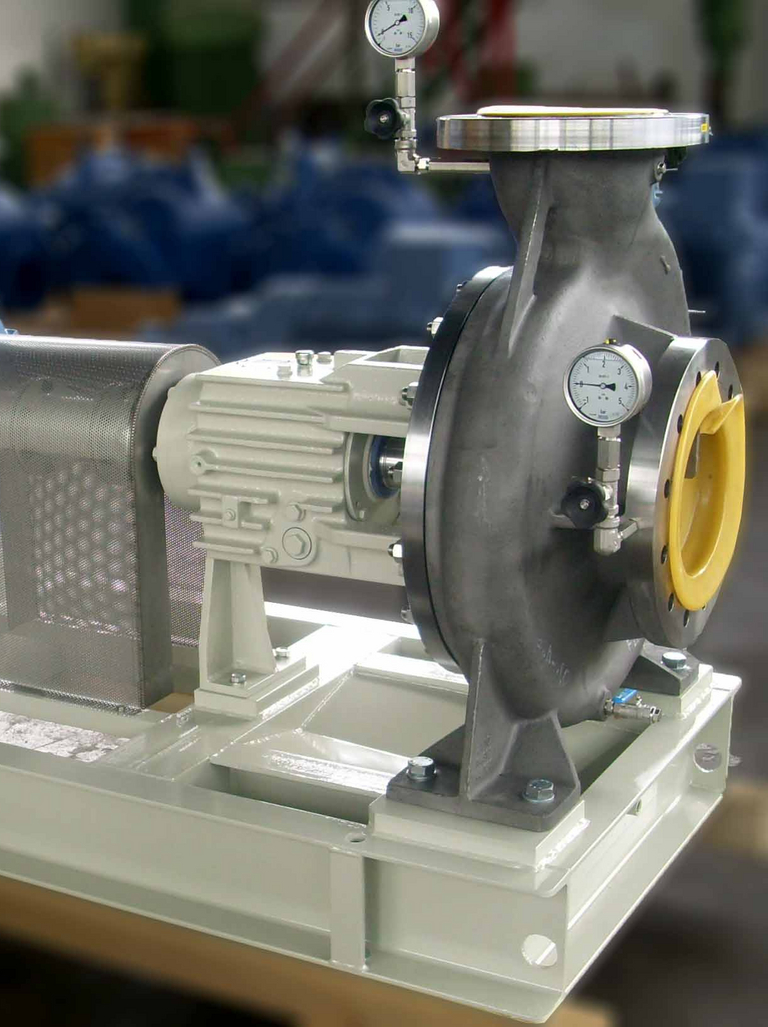

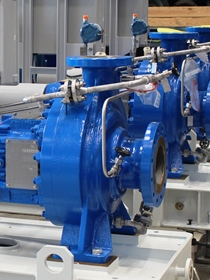

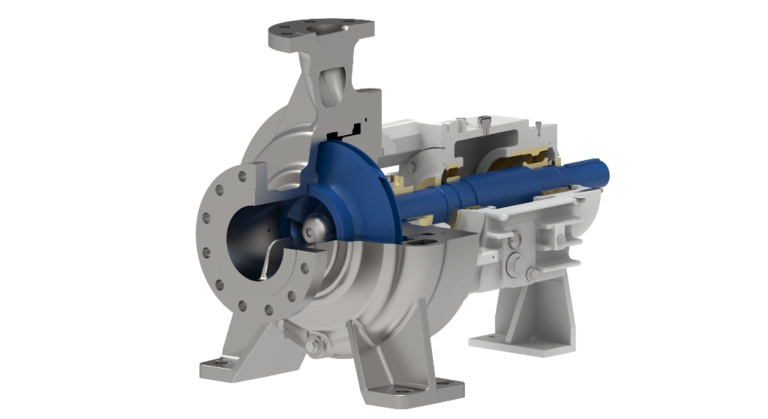

The OH1 KRP pump from Apollo is a foot-mounted centrifugal pump designed for challenging industrial applications. Meeting the standards of API 610 and ISO 5199, it offers the highest levels of reliability and efficiency. The back-pull-out design is a standout feature, allowing for easy maintenance without having to dismantle piping. This reduces downtime and lowers operating costs. Interchangeable wear rings and impellers also extend the pump's lifespan and minimise maintenance costs. Thanks to its robust construction, the KRP pump is ideal for use in the chemical and petrochemical industries.

- axial suction nozzle, radial discharge nozzle

- foot-mounted

- casing > NW 80 of double-volute design

- reduction of axial forces

- low vibration – long service life

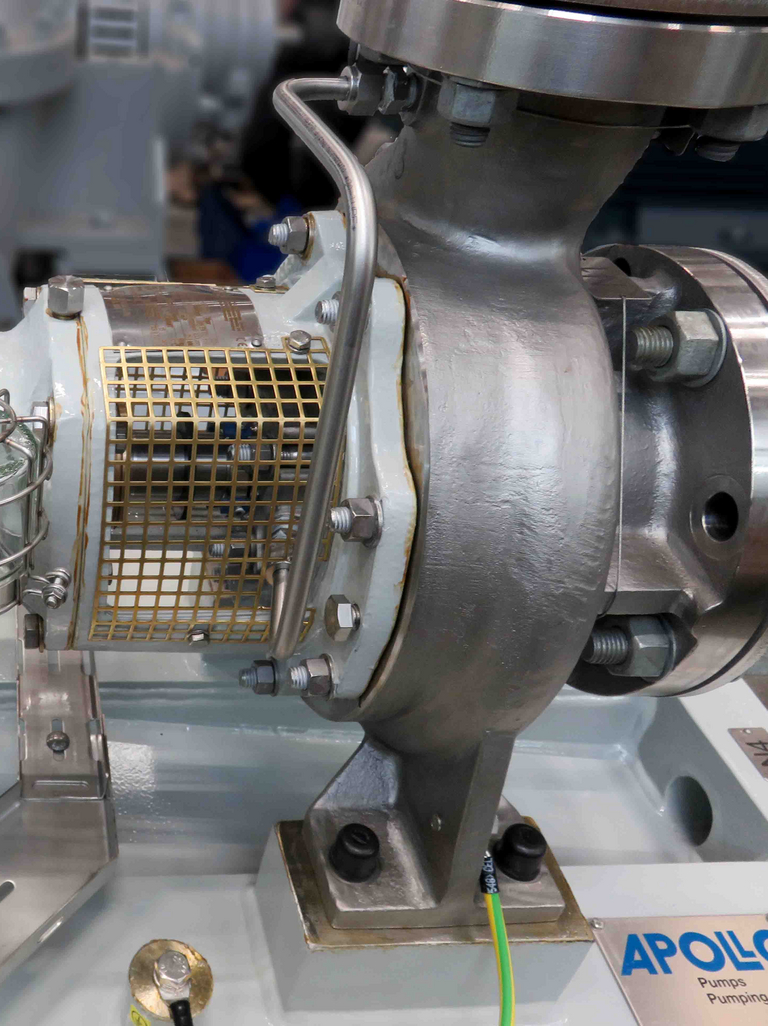

- back-pull-out version in connection with demountable coupling allows simple maintenance, volute casing and motor remain in initial position

- seal area acc. to API 610/682, suitable for a variety of seals

- standard version

- flanges according to ASME B16.5 for class 300 or 600 lbs

- exchangeable wear and guide rings enable easy maintenance and cost reduction

- dynamically ballanced impellers guarantee very smooth running

- robust shaft design meets all requirements of API-610

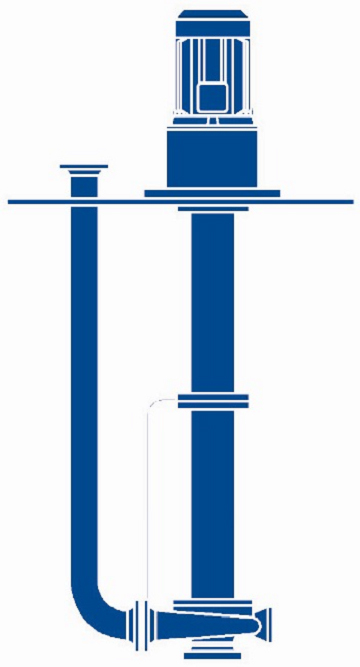

- Vertical volute-casing pumps for wet or dry installation with most different submersion depth up to 8 m

- Shaft on drive side with robust pair of angular ball bearings of long lifetime running in the pump in maintenance-free slide bearings

- Slide-bearing locations are lubricated by means of liquid to be pumped via lubrication piping.

- Bearings with oil or grease lubrication, optionally we can provide bearing cooling.