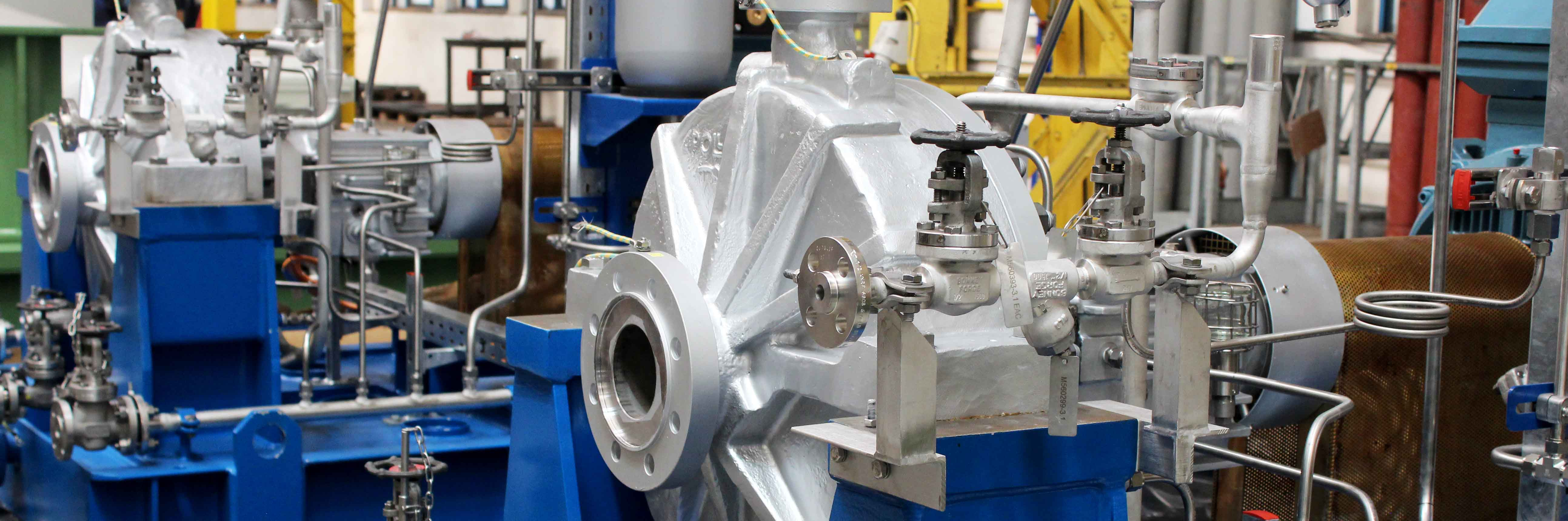

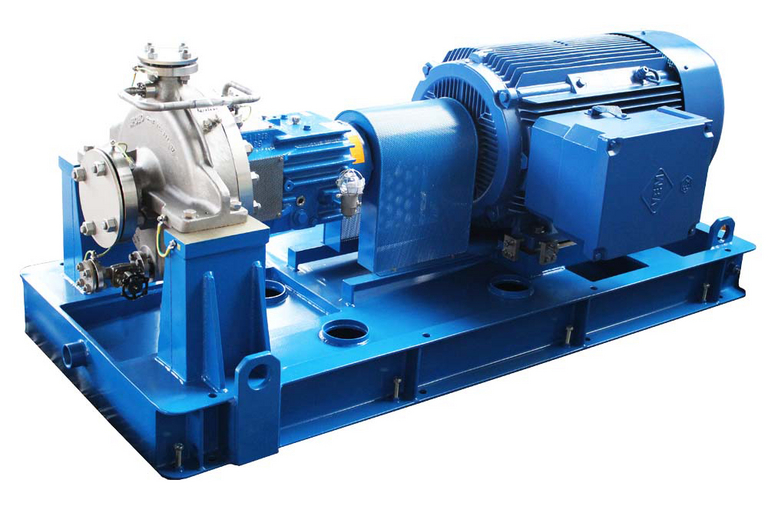

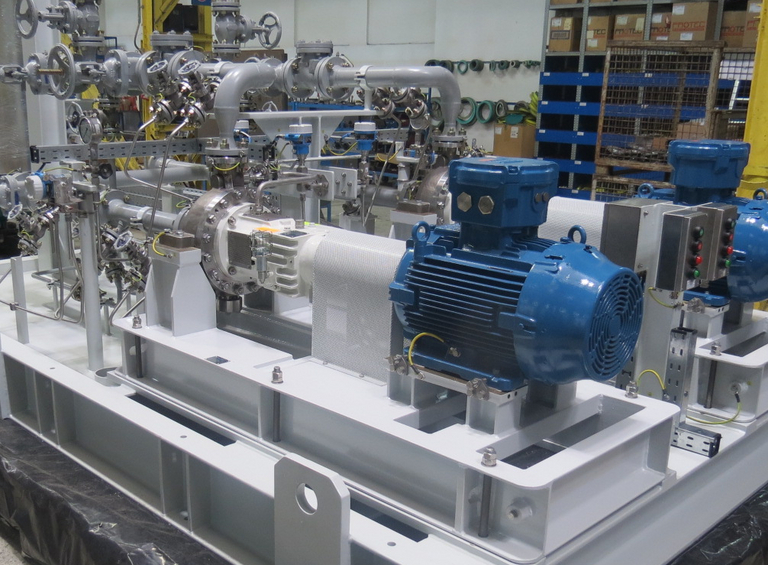

The single-stage, horizontal, heavy version is designed acc. to the requirements of API 610 and ISO 5199. The robust design of the pumps, as well as the reliable hydraulic version, enable to fulfillment of all requirements of the application in many fields.

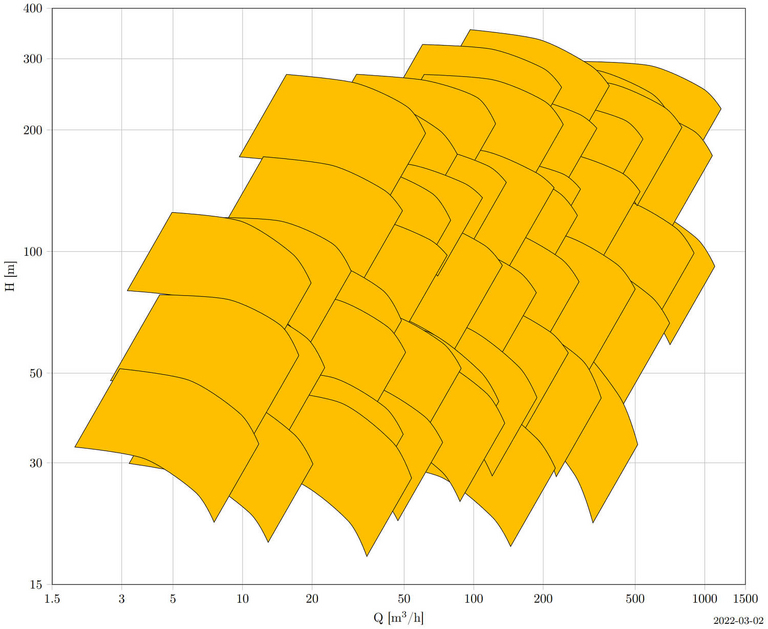

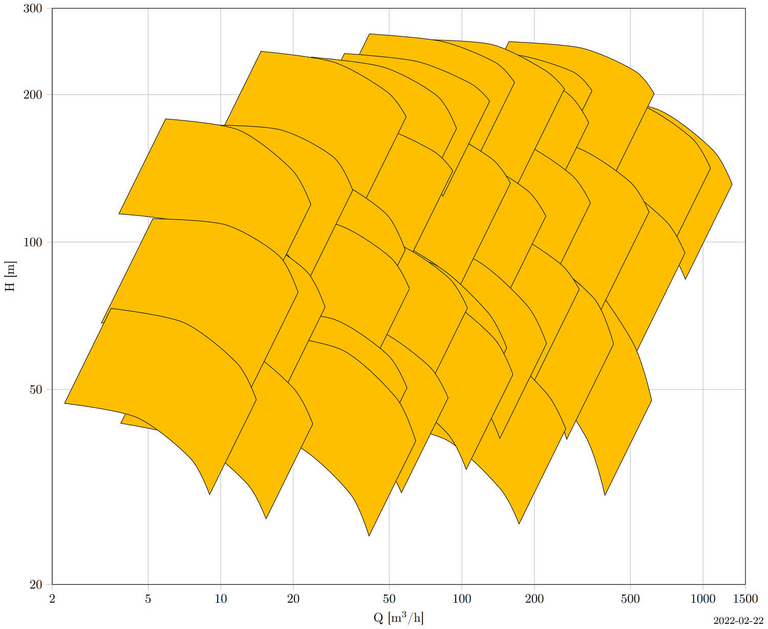

| KRH | KRHA | |

|---|---|---|

| Q (m³/h) | 1000 | 5000 |

| H (m) | 320 | 220 |

| P (bar) | 55 / 90 | 55 |

| T (° C) | +450 | +450 |

Volute casing pumps of type KRH are applied in processing plants where complicated processing problems of liquid pumping have to be solved. Clean and slightly contaminated, cold and hot, chemically neutral or aggressive liquids can be pumped with these pumps.

- Petrochemical Plants, Refineries

- Chemical Industry/Process Engineering

- Sugar Industry

- Power Plants

- Desalination Plants for Sea Water

- Environmental and Offshore Engineering

- Treatment Plants for Mineral Oil Systems, etc.

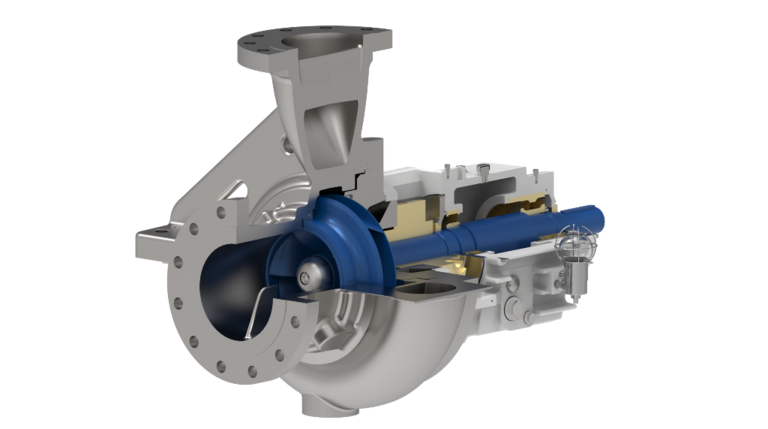

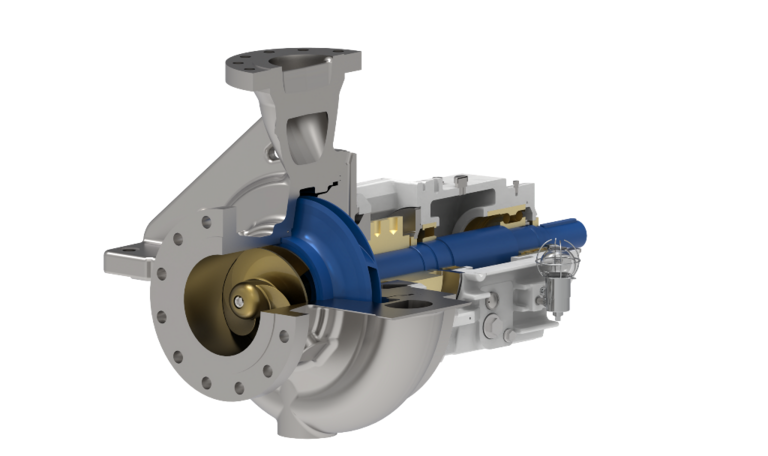

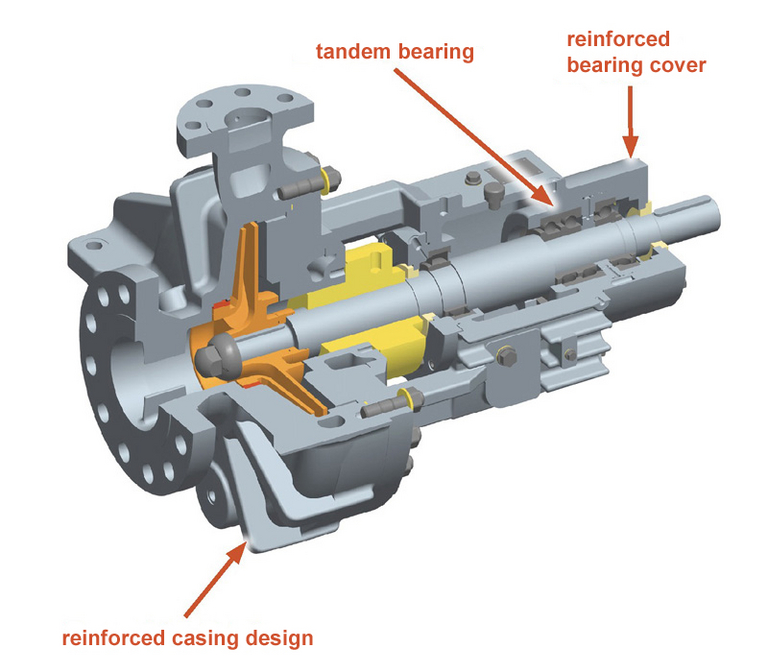

- axial suction nozzle, radial discharge nozzle

- centerline-supported

- casing > NW 80 of double-volute design

- reduction of axial forces

- low vibration – long service life

- back-pull-out version in connection with demountable coupling allows simple maintenance, volute casing and motor remain in initial position

- seal area acc. to API 610/682, suitable for a variety of seals

- standard version

- flanges according to ASME B16.5 for class 300 or 600 lbs

- exchangeable wear and guide rings enable easy maintenance and cost reduction

- dynamically ballanced impellers guarantee very smooth running

- solid shaft design meets all requirements of API-610

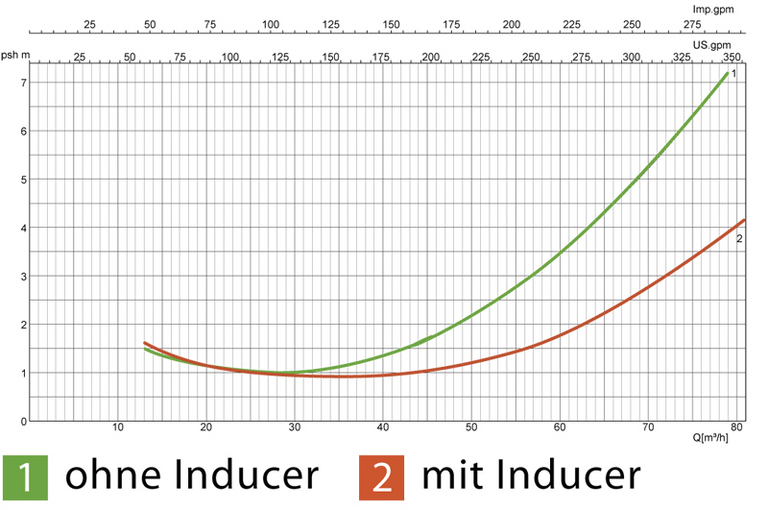

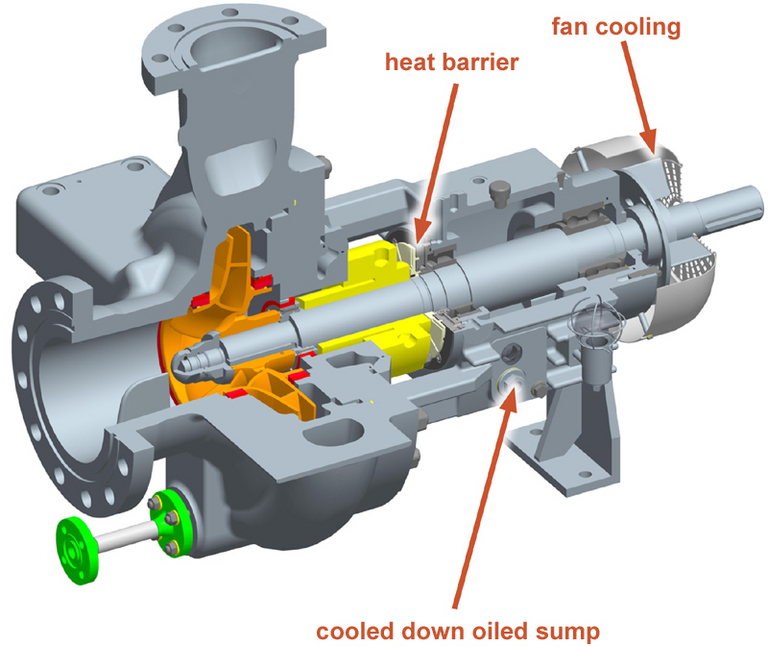

- temperature up to 450 °C

- high process safety also on very high temperatures

- special sealing concept for high temperatures

- mechanical seal + barrier fluid system according to API-682 for high temperature

- heat barrier prevents penetration of heat into bearing

- fan cooling and cooled down oil sump ensure low bearing temperature

- cooling of seal chamber