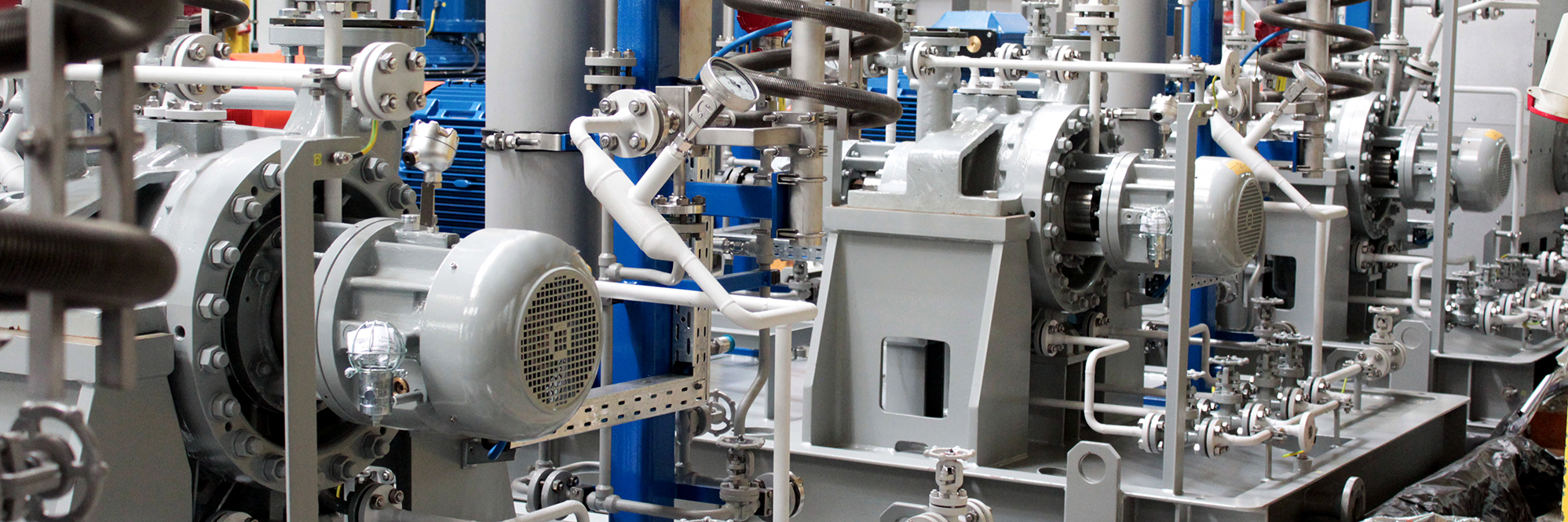

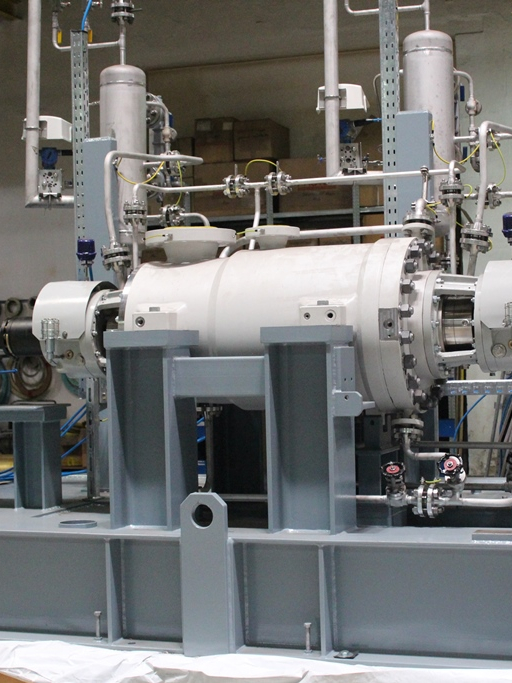

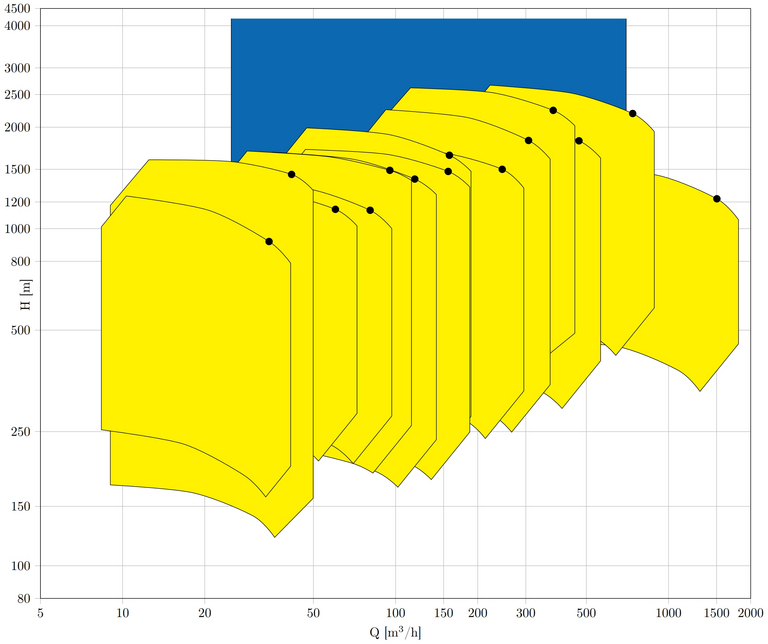

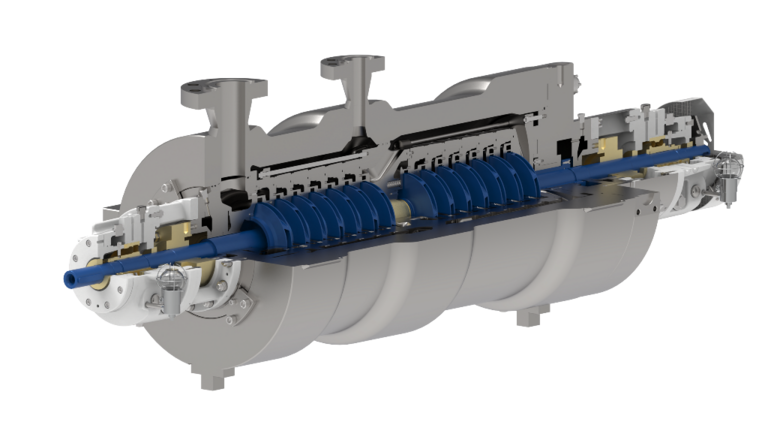

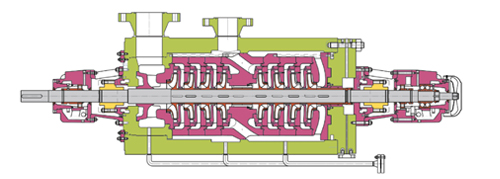

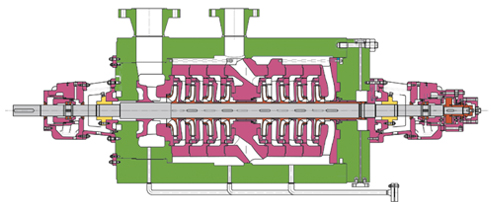

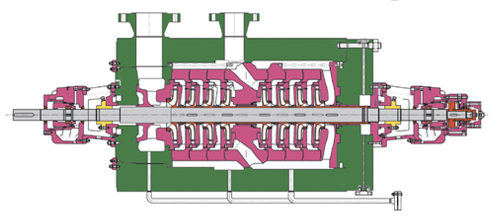

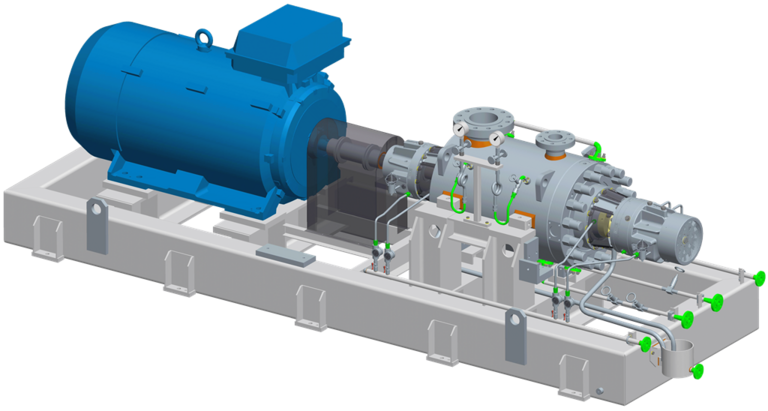

Multistage, horizontal high-pressure pump in barrel design, as back-to-back version. The process pump is particularly suitable for big volumetric flow rates and has a modular design for the best possible adaptation to customers’ requirements and low operating costs.

| TG | |

|---|---|

| Q (m³/h) | 1 800 |

| H (m) | 4 200 |

| P (bar) | 450 |

| T (° C) | +420 |

Based on the excellent hydraulic characteristics and the high reliability in critical applications, the pumps are suitable for applications such as:

- applications in the oil and gas industry

- offshore applications

- booster applications in all industrial branches

- water injection onshore and offshore

- boiler feed water applications

- the “pull-out” version ensures maximum serviceability. Barrel remains in the piping. The pump as an insert unit can be dismantled and serviced.

- very short standstill time during maintenance work thanks to cartridge design

- 1st stage designed as NPSH stage

- sealing area designed according to API 610 / 682

- centerline-supported

- single impeller support depending on design

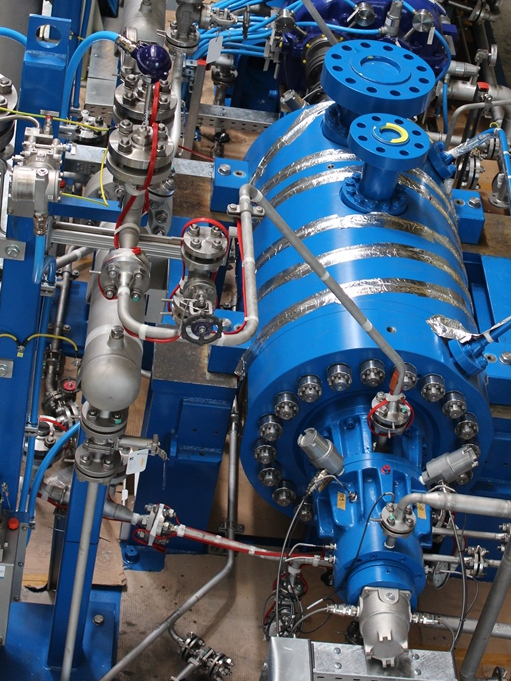

- API 610 requires stable rotor dynamics even on double clearance - a „back-to-back“ arrangement with bearing in the middle fulfills this requirement

- suitable for high number of stages and high speeds even on small viscosity

- small bearing loads by compensation of axial thrust

- wear of casing wear rings has just very small influence upon axial thrust

- pump is especially suitable for critical application cases and high speeds

- Q= 700 m³/h

- H= 4200 m

- P= 450 bar

- T= +360 °C

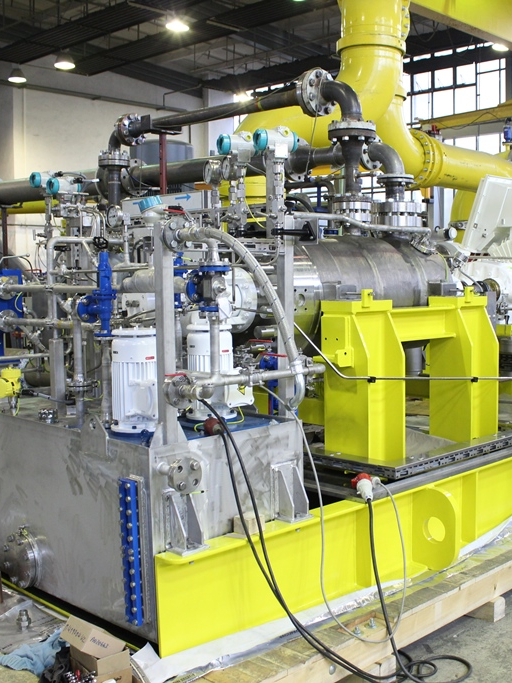

- version for speeds up to 6000 r.p.m.

- as a result of speed increase reduction of number of stages and investment cost

- special rotor design for high speeds

- exact analysis of critical speeds ensures stable runability in the whole operating range

- radial-axial slide bearings with forced oil lubrication

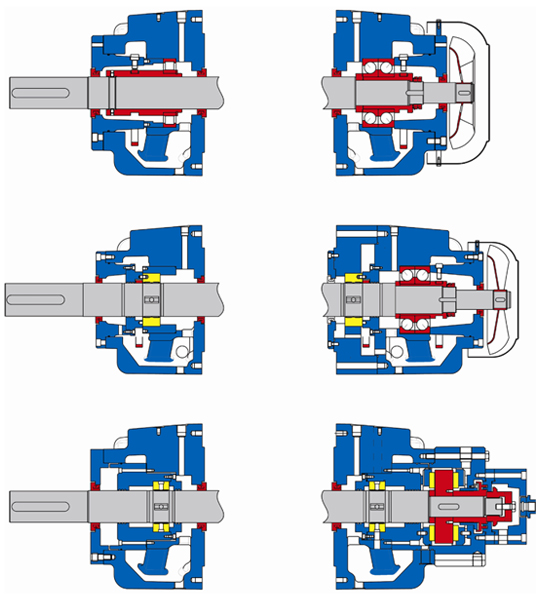

- Standard Version

Radial bearings: antifriction bearings

Axial bearings: antifriction bearings

Ring oil lubrication

- Variant

Radial bearings: slide bearings

Axial bearings: antifriction bearings

Ring oil lubrication

- Variant

Radial bearings: slide bearings

Axial bearings: slide bearings

Pressure oil lubrication

Type series: TL / TG