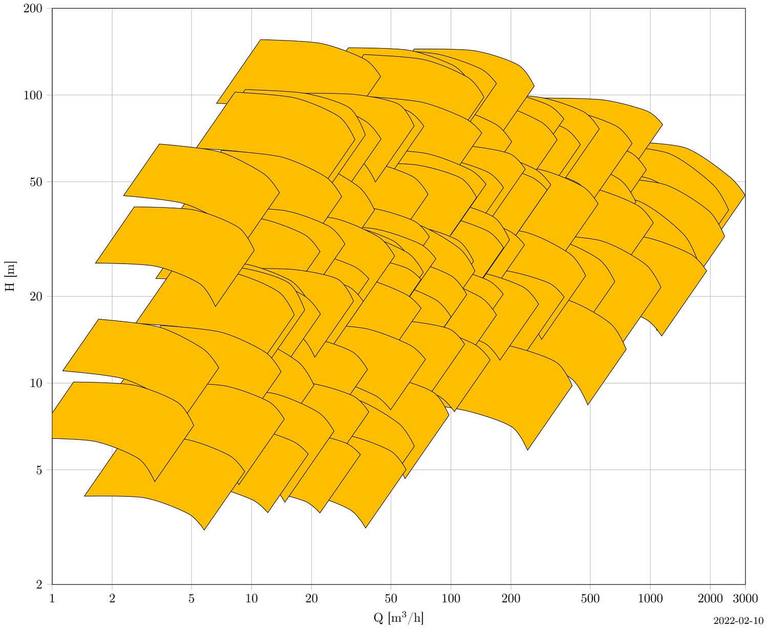

Volute pumps of type series KRC have been designed for pumping aggressive, poisonous, explosive, hot and cold liquids in processing plants of all kinds. The version with an open impeller and wear plate enables to pump of polymerizing, cloddy, and gas-loaded liquids. This enables the application of these pumps in various fields of chemical engineering and process technology:

- organic and inorganic e. g. plastics, paints, soaps and cleaning detergents, fertilizers, crude oil extraction and processing

- process technique e. g. power generation, waste disposal, flue gas desulfurization, environmental engineering

- paper production, pharmaceutics, bioengineering

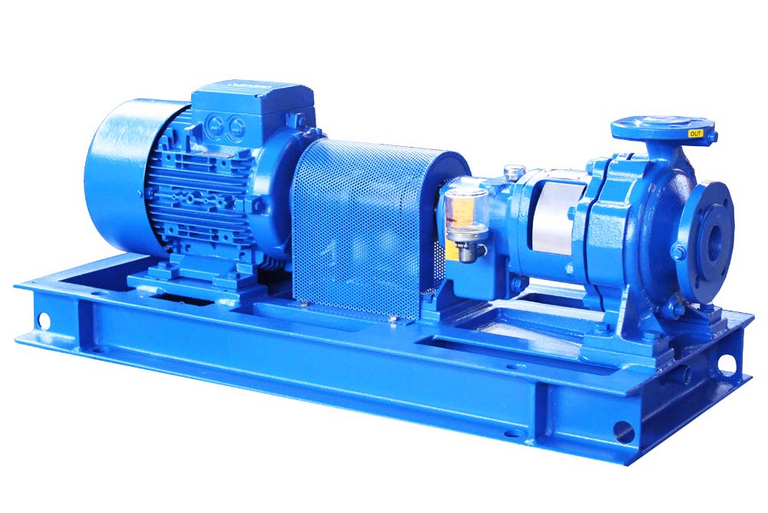

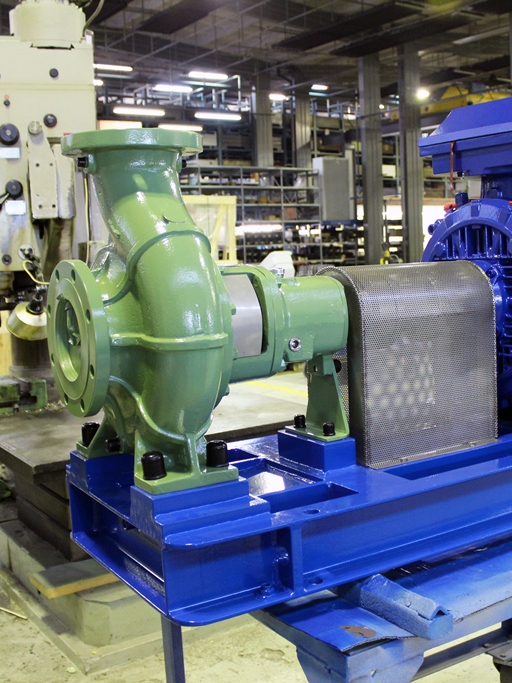

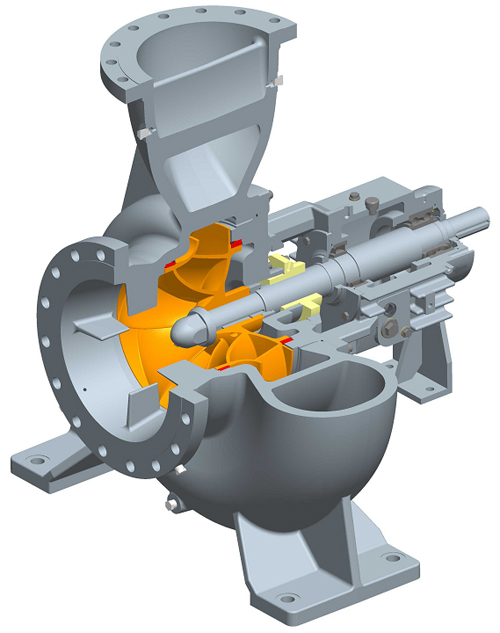

- single-stage, one-flow, normal-priming volute-casing pump with dimensions according to DIN EN 22858 or ISO 2858.

- the design fulfills the requirements of DIN 5199

- standard features are the horizontal version with oil-lubricated bearing housing, axial suction nozzle and vertical discharge nozzle

- optionally: vertical installation or block-type version with flanged motor

- grease lubrication is available for special application cases

- optionally an inducer can be installed for the improvement of NPSH value