Our high-performance pumps, which are designed according to API 610 standards, are characterised by their reliability, efficiency and robustness. Our product range includes models BB1, BB2, BB3, BB4 und BB5.

Was sind BB-Prozesspumpen?

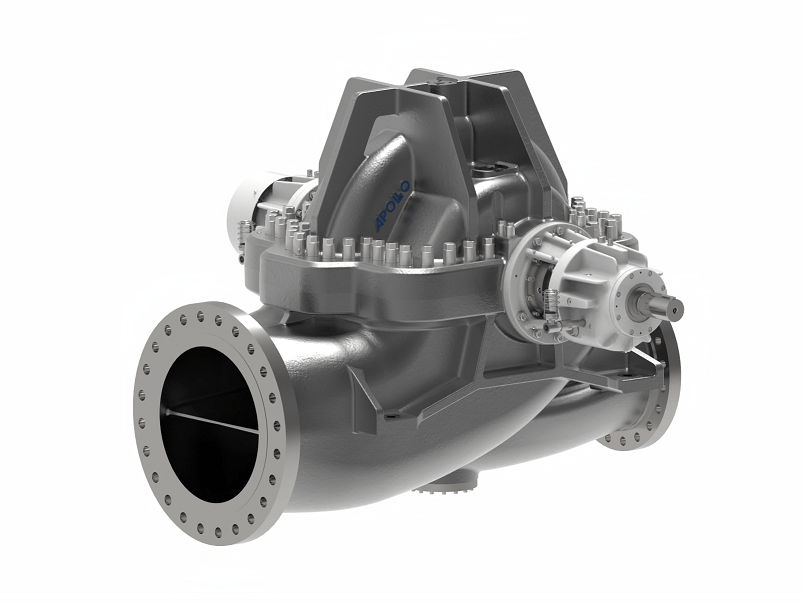

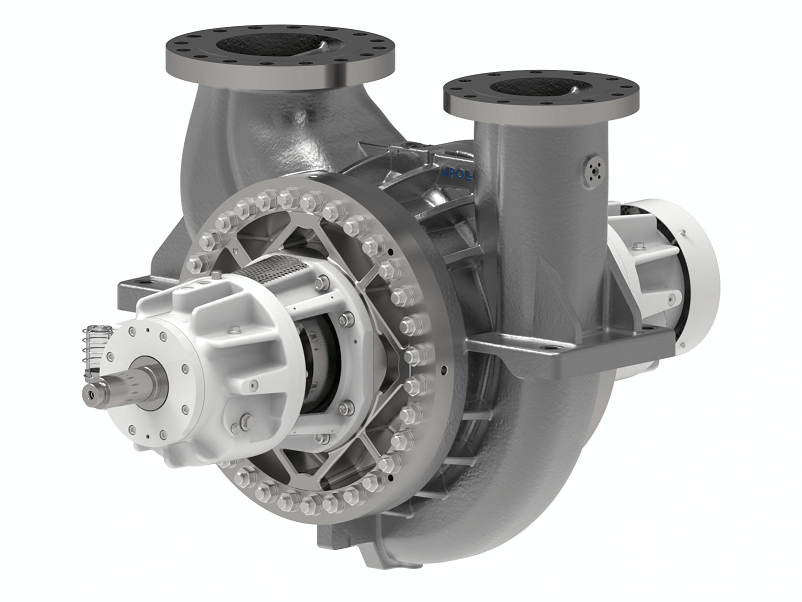

BB process pumps are specialised centrifugal pumps with between-bearing design. Designed according to the API 610 standard (ISO 13709), they are used in the oil and gas industry. Support on both sides of the rotor provides stability and enables operation under high loads. These pumps are available in many variations, including single or double casing with axial or radial splits, as well as single-stage or multi-stage options. With their various sizes, hydraulics and materials, these pumps are suitable for high-pressure, high-temperature applications where reliable, efficient performance across a wide flow range is essential.

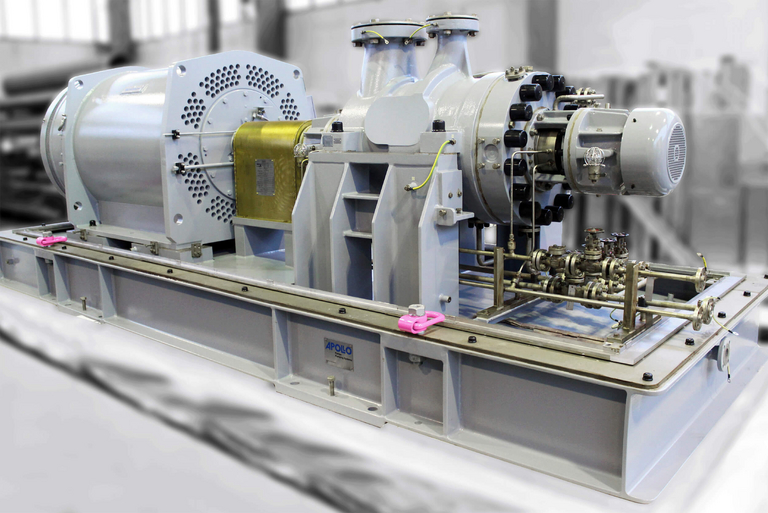

Product overview of pumps with bearings on both sides

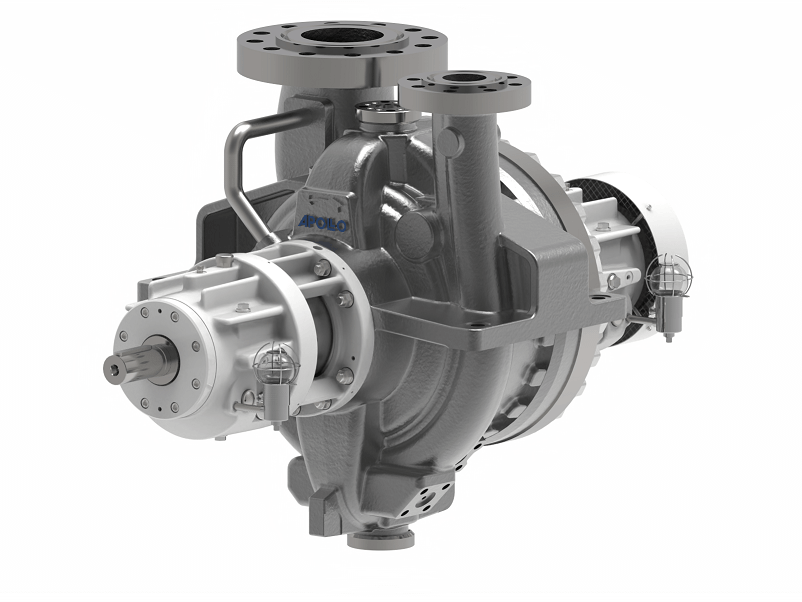

The BB1 pump is a heavy-duty, single-stage, axially split process pump characterised by its simple installation and maintenance-friendly design. Its axial split housing and compact design enable short downtimes, thereby optimising the efficiency of your systems. This pump is particularly well-suited to transporting large volumes of water and offers reliable performance in demanding applications.

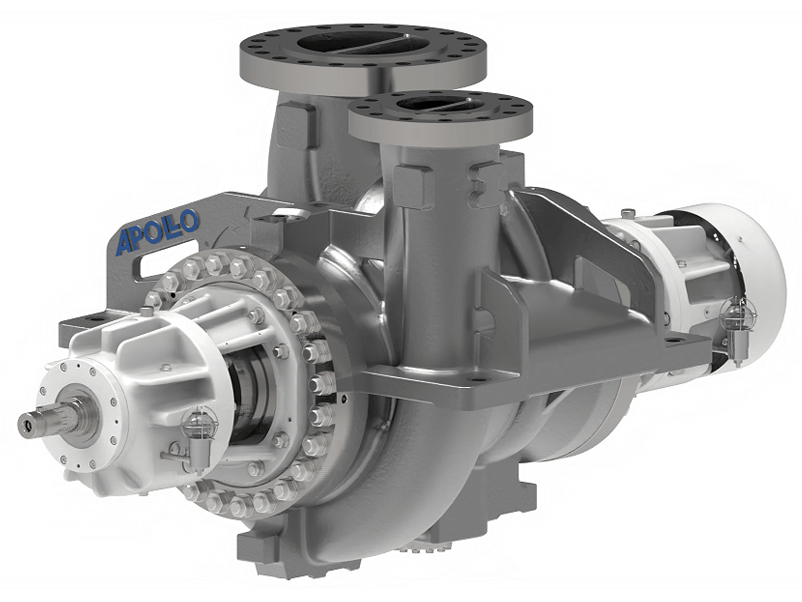

BB2 pumps are characterised by their excellent hydraulic performance and are ideal for applications requiring high pressures and temperatures. Apollo offers two types of BB2 pump. The ZPR/ZPRA models are horizontal, single-stage, radially split process pumps equipped with a double-flow impeller and bearings on both sides. The KGR / KGRD models, on the other hand, are two-stage, heavy-duty process pumps with bearings on both sides.

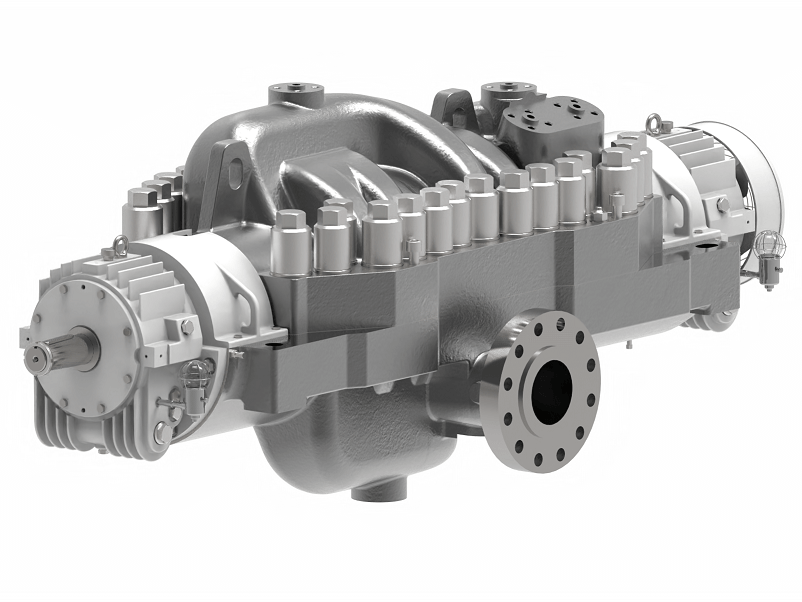

BB3 pumps are horizontal, multi-stage, high-pressure pumps with an axially split casing and bearings on both sides. This pump type is specially designed for extremely demanding applications. Maintenance is straightforward as the casing is axially split, meaning that it is not necessary to remove the piping.

BB4 pumps are particularly suitable for use in modern power stations. Apollo offers two types of BB4 pump. The HP series are horizontal, multi-stage, radially split, high-pressure pumps with a modular design. The GP pump types, on the other hand, are multi-stage, high-pressure, counter-rotating (back-to-back) pumps. Apollo also offers a custom-made version of the BB4 pump. Designed for large volume flows, the GMHD Apollo pump is a horizontal, multi-stage, high-pressure pump with a double-flow NPSH impeller.

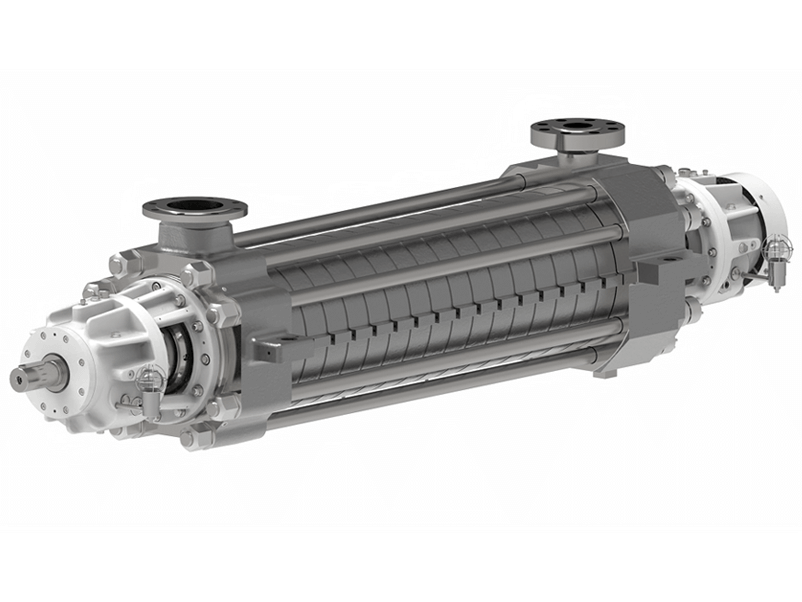

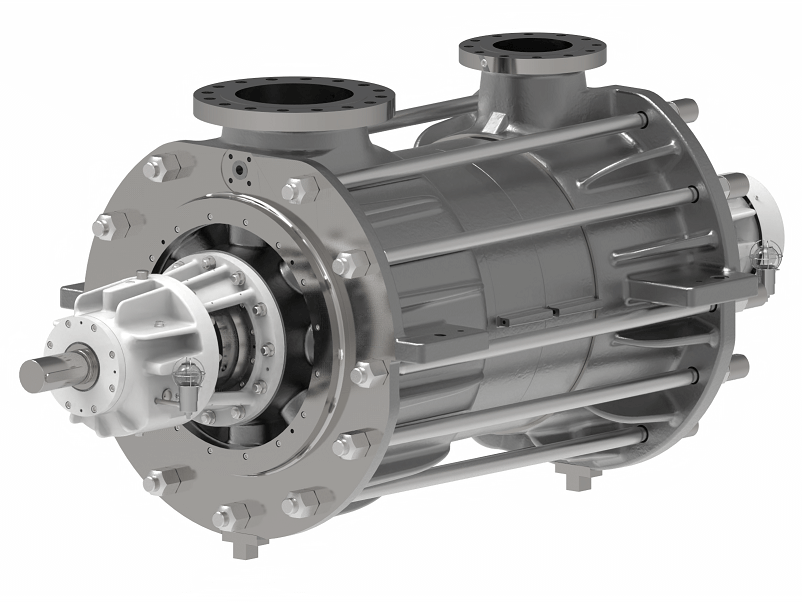

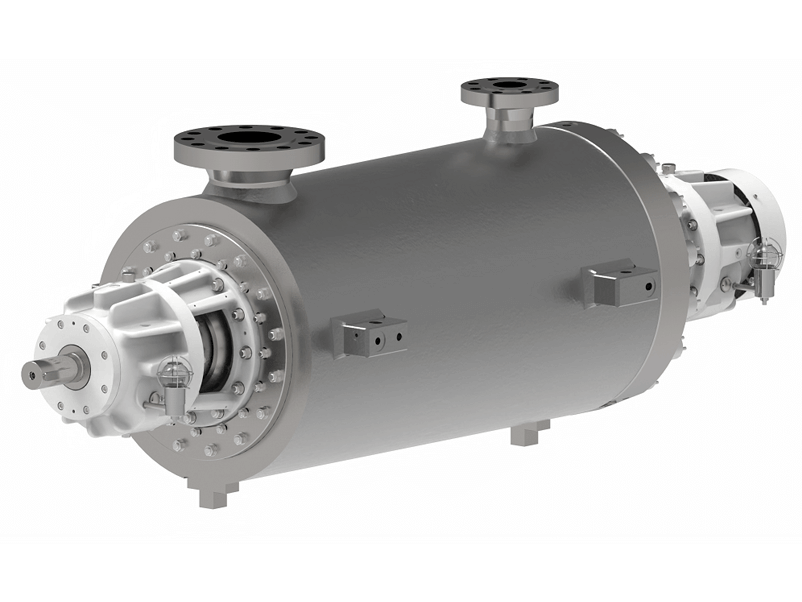

Apollo offers two variants of the BB5 barrel pump: the TL pump, which is a horizontal, multi-stage, high-pressure pump with an in-line impeller arrangement in a barrel design; and the TG pump, which is also a multi-stage, high-pressure pump in a barrel design with a counter-rotating rotor (back-to-back). Both pumps are suitable for all high-pressure applications.

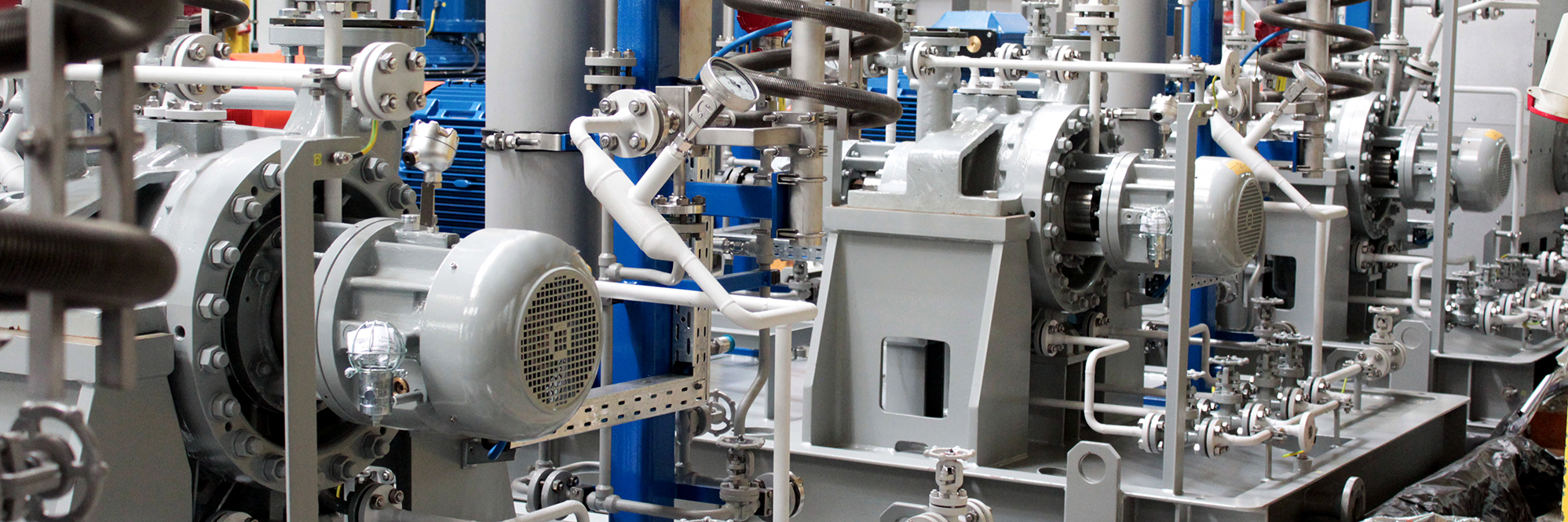

Typical applications of BB Pumps

BB pumps are used in many industrial sectors, particularly in oil and gas, petrochemicals, and power plant technology. They are typically used in refineries, where they play a crucial role in the extraction of crude oil and various chemical products. In petrochemical plants, BB pumps ensure the efficient processing and safe transportation of chemicals and other liquids. In power plants, they are indispensable for circulating cooling water, boiler feed water and other operating fluids, which contributes significantly to optimal system performance.

FAQs about centrifugal pumps with bearings on both sides

Our pumps are made from high-quality materials, including cast iron, cast steel, stainless steel, austenitic steel, duplex steel and super duplex steel. We also use renowned alloys, such as titanium and Inconel, to ensure corrosion resistance and durability. We also offer special alloys that meet the strict NORSOK and NACE specifications, ensuring they are optimally suited to your application's specific requirements.

The frequency of maintenance depends on the operating conditions and the application. Thanks to the dual bearing design, however, longer maintenance intervals are possible. Maintenance frequency depends on operating conditions and application. Thanks to the double-sided bearings, however, longer maintenance intervals are possible. Regular maintenance and inspection will extend the service life of your pumps. If you have any questions or require any service, please email us at service (at) apollo-goessnitz.de.

We offer highly specialised, tailor-made solutions precisely designed to meet the individual needs of our customers. We are happy to provide detailed advice. To receive an optimal solution, please send us your precise requirements by email at sales (at) apollo-goessnitz.de.

Should you require information regarding the various API 610 pump types, please refer to the website or contact sales (at) apollo-goessnitz.de directly.

![[Translate to English:]](/fileadmin/_processed_/0/9/csm_BB5-TG-80M-15.20_a60e91da74.png)