ON THE TEST STAND - PUMPS AND SYSTEMS

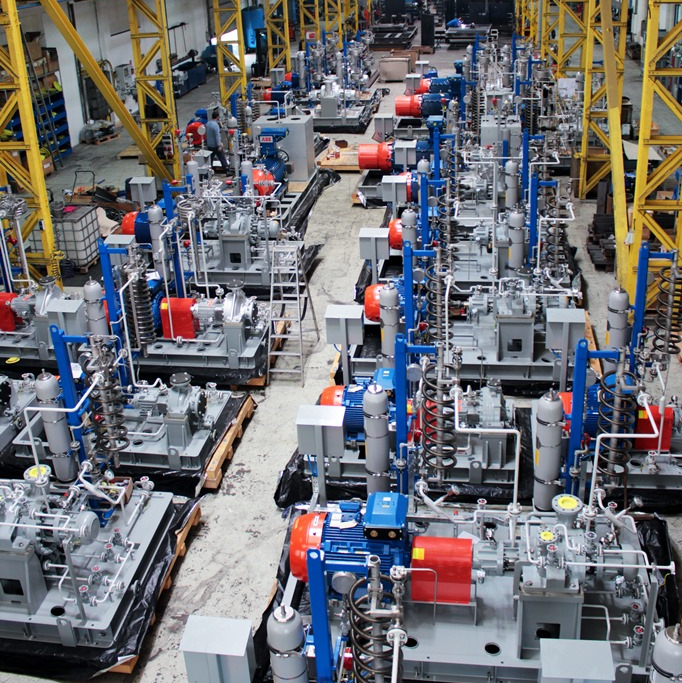

A careful inspection is carried out before delivery of each pump unit. Our team consists of experts who ensure that each installation is in perfect condition before it is delivered. Our mission is to provide you and other customers with high-quality products. There may be a problem even in the best system. In this case, a quick analysis of the reasons is necessary. Apollo offers the customer a comprehensive troubleshooting service so that the causes of the problems can be found.

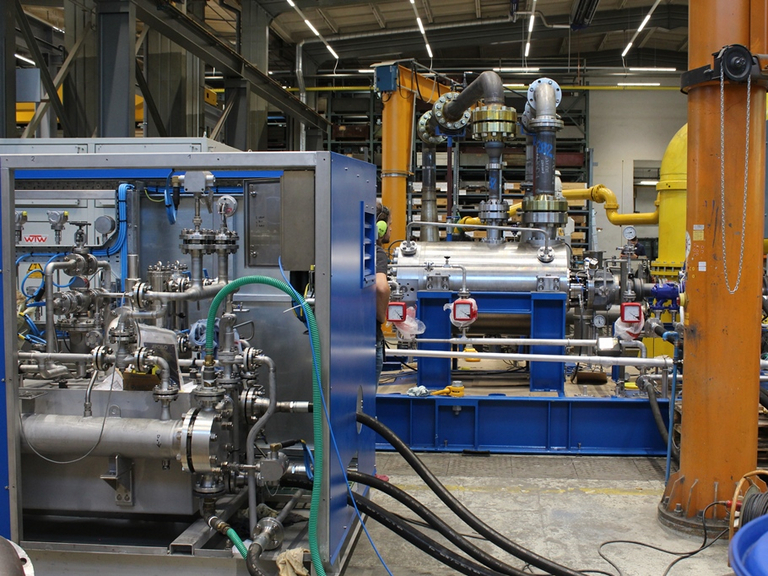

Test Field

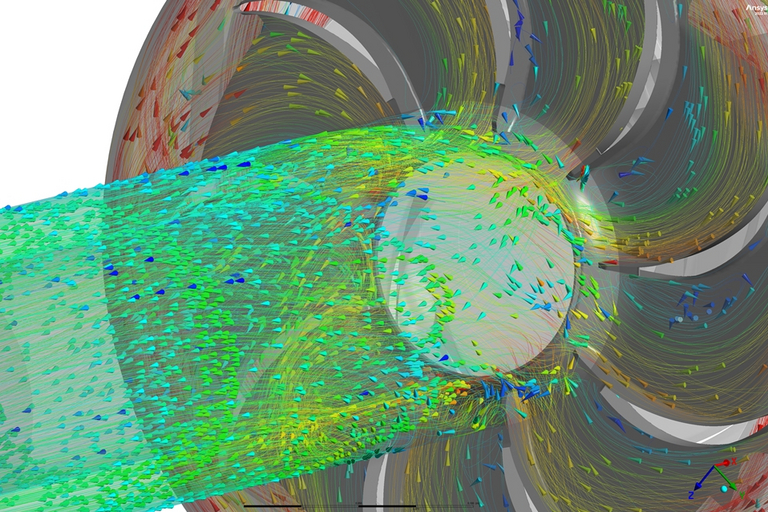

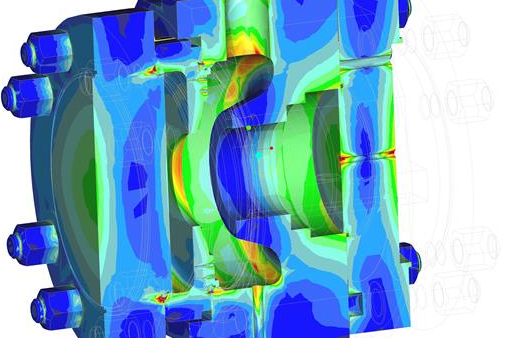

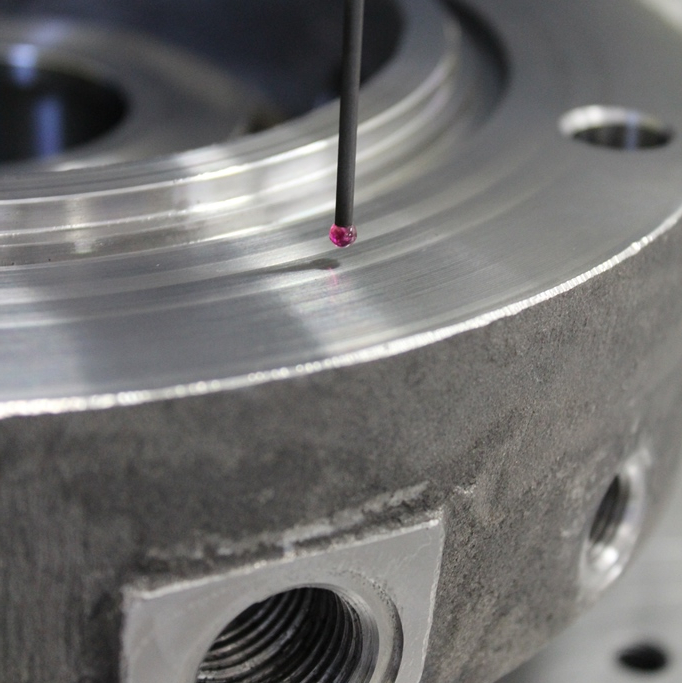

Most up-to-date test stand units ensure application-real test conditions, such as testing with 50/60 Hz Motors; up to high power ranges we have at our disposal frequency converters and tests with voltage levels of 400 V up to 13 kV. Our many-sided test stand enables the testing of complete pump units as specified in various Specifications and Standards. Also in the range of System Engineering we have at our disposal Test fields for testing of complete pumping systems.

Modern multifunctional machines with a high degree of automation, multi-machine operation, our own sandblasting and painting facilities, pump and system assembly as well as welding and electrical engineering departments guarantee efficient cooperation between all company divisions, fast processing times, high manufacturing flexibility and location protection.

QUALITY ASSURANCE - OUR PRIORITY

Apollo is ISO 9001 certified and has established a complete quality management system that complies with all relevant laws, standards and regulations. This ensures the high quality of products and services. Apollo continuously improves its processes and provides a flexible response to customers' changing requirements.